YZ Systems is a global solutions provider, and service to the customer is still our priority. Our product line spans from electronically controlled crude oil and light liquid samplers to include: the DynaPak electronically controlled natural gas samplers; the industry leading odorant injection system, NJEX; and the revolutionary new odorant detection system, DTEX. YZ was founded in 1949 in Snyder Texas as a small engine mechanic shop by I.V. Zeck to serve the drilling industry in the local oil field. Having quickly developed a reputation for expert servicing of oil-field drilling engines, local engineers asked YZ to design and build specialty drilling and production products to meet specific their needs.

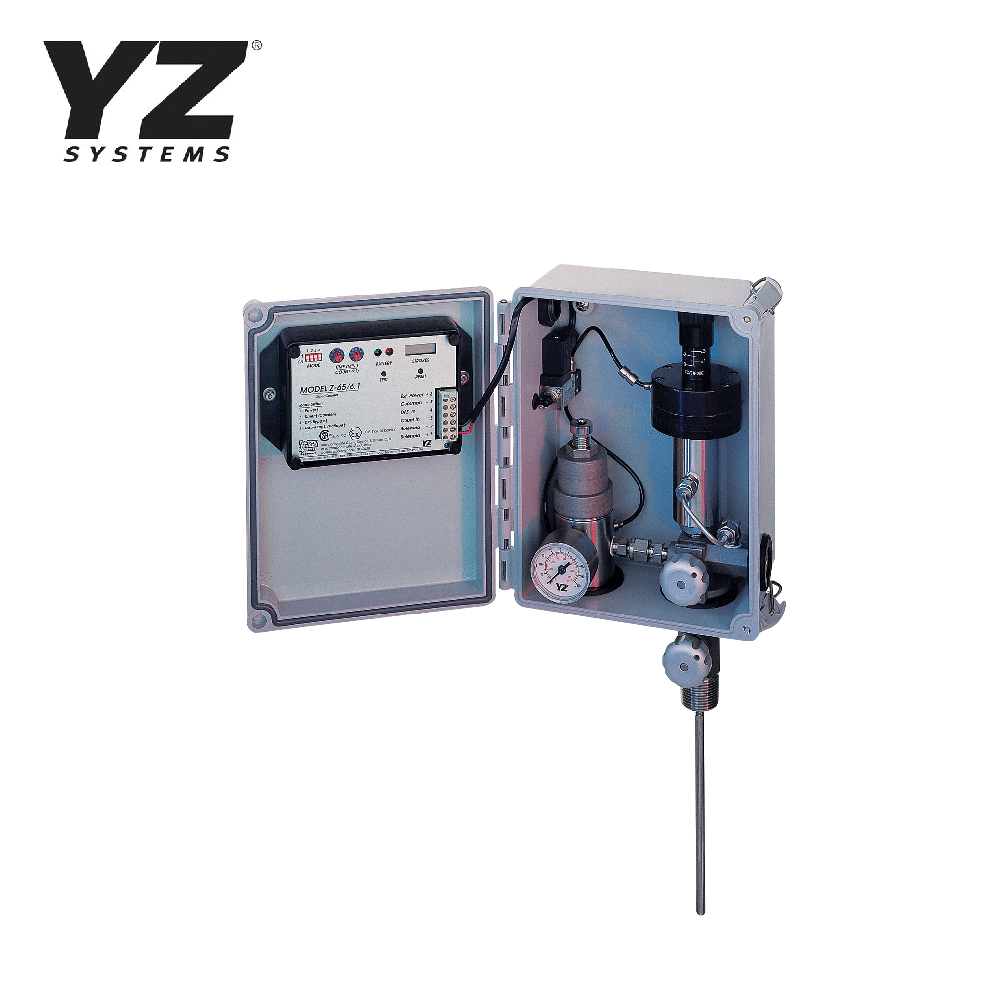

DYNAPAK SAMPLING SYSTEMS

DESCRIPTION

DynaPak is the industry standard in simplicity and reliability. Designed to deliver a representative sample of natural gas or light liquids the DynaPak sampling system has become the industry standard in simplicity and reliability. Whether sampling condensate on an offshore platform or natural gas on shore you can have confidence the Dynapak will provide years of dependable service.

FEATURES

>> Operation : Proportional to flow

>> Operation : Proportional to time

>> Intrinsically safe

>> Battery operated

>> Simple design

SPECIFICATION

>> Z-65 Controller

>> Dynapak sample pump

>> High pressure filter/regulator

>> Weather proof enclosure

>> Multiple mounting configurations available

DOWNLOAD DOCUMENT

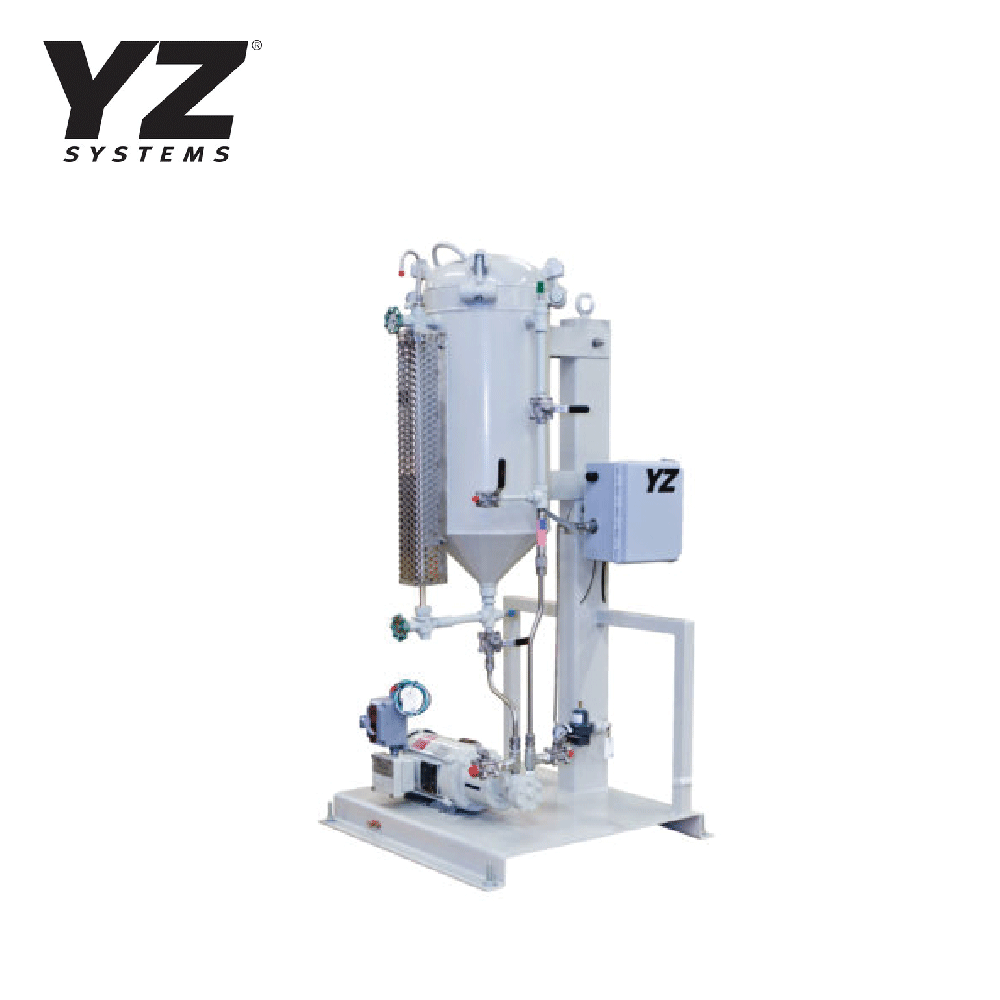

CRUDE OIL SAMPLING SYSTEMS

DESCRIPTION

Simple and reliable family of crude oil sampling systems. YZ offers a standard, simple and reliable family of crude oil sampling systems. Each system is manufactured with quality and precision. The goal of the entire design is to deliver a representative sample month after month, year after year.

FEATURES

>> Factory assembled

>> Single or multi-vessel accumulators

>> Sample pump with integral balance feature

>> Skid or cabinet mounted

>> Sample Accumulator with spray bar, epoxy lined

>> Static mixer

>> Proportional to flow operation

SPECIFICATION

>> Skid or cabinet mounted

>> Sample pump: direct or remote mount

>> Accumulator with spray bar, epoxy lined

>> Control options – variety

DOWNLOAD DOCUMENT

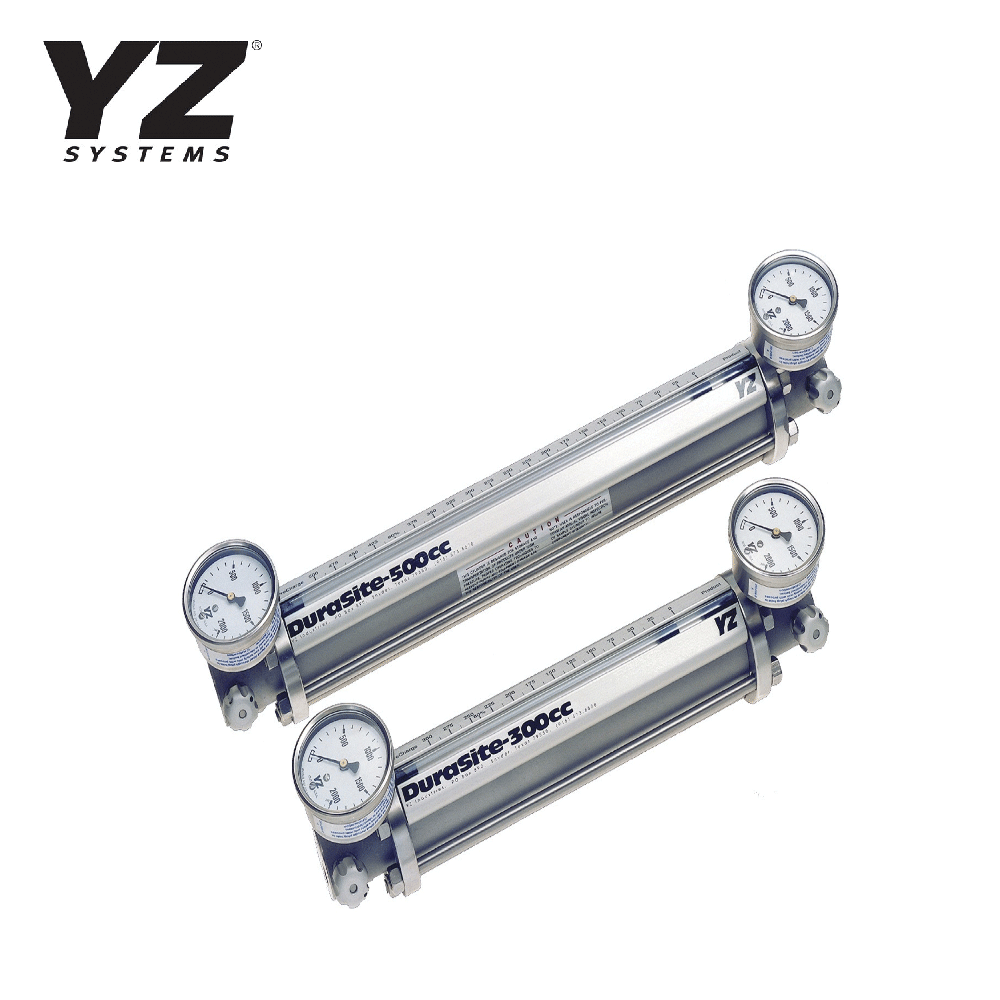

DURASITE CONSTANT PRESSURE SAMPLE CYLINDER

DESCRIPTION

The DURASITE Constant Pressure Sample Cylinder is designed to provide years of accurate trouble-free sample gathering. The DURASITE is a patented product from YZ Systems and is DOT approved (Patent #4,409,850, DOT exemption #8757). Our DOT certification allows the transport of hydrocarbons up to 1,800 psig by motor vehicle or cargo aircraft. This unit incorporates a free-floating piston design to provide a product chamber and a precharge chamber. Once a precharge of inert gas has been applied to the DURASITE Cylinder, constant pressure of the product can be maintained during sampling, transit and evacuation. The magnetic volume indicator “bullet” from YZ Systems provides excellent visual indication of the product. Internally, a patented design incorporates an inert mixing ball to allow safe product mixing.

FEATURES

>> Exploration and production

>> Pipeline transport

>> Midstream applications

>> Floating production storage and offloading (FPSO)

SPECIFICATION

>> Standardized designs

>> Commitment to safety and quality

>> Service and support

>> Years of experience and proven track record

DOWNLOAD DOCUMENT

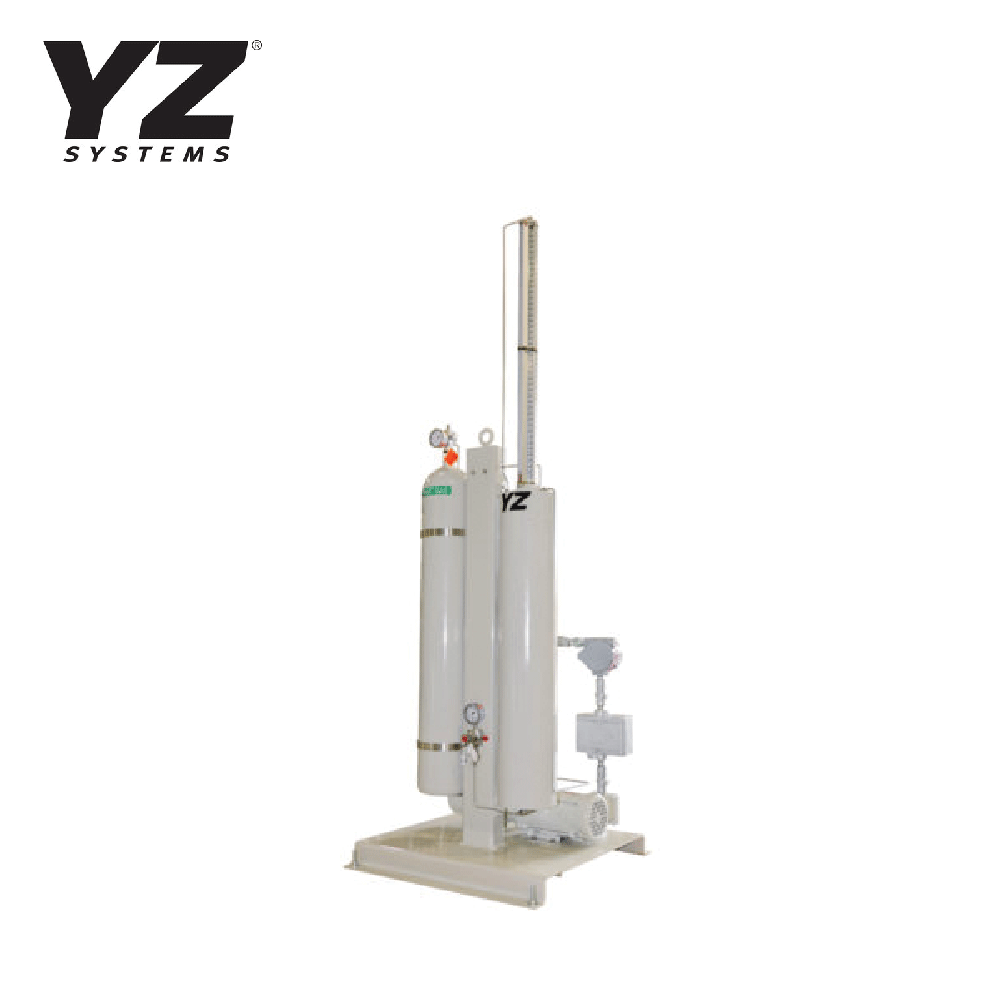

LIGHT LIQUID SAMPLING SYSTEMS

DESCRIPTION

Light Liquid Sampling Systems offer a versatile solution to a wide range of sampling applications. YZ has been providing the energy industry Light Liquid Sampling systems for over 60 years. Our innovative design offers a versatile solution to a wide range of sampling applications such as propane, butane and other refined products. A simple skid or a multi-vessel system with remote communications are available to meet your process needs. Each system comes with YZ’s commitment to quality and “low cost of ownership”

FEATURES

>> Factory assembled

>> Sample pump w/ integral balance feature

>> Skid or cabinet mounted

>> Sample Accumulator w/ power mixer

>> Proportional to flow operation

SPECIFICATION

>> Skid or cabinet mounted

>> Sample pump: Direct or remote mount

>> Accumulator w/power mixer

>> Precharge vessel

>> Control options- variety

DOWNLOAD DOCUMENT

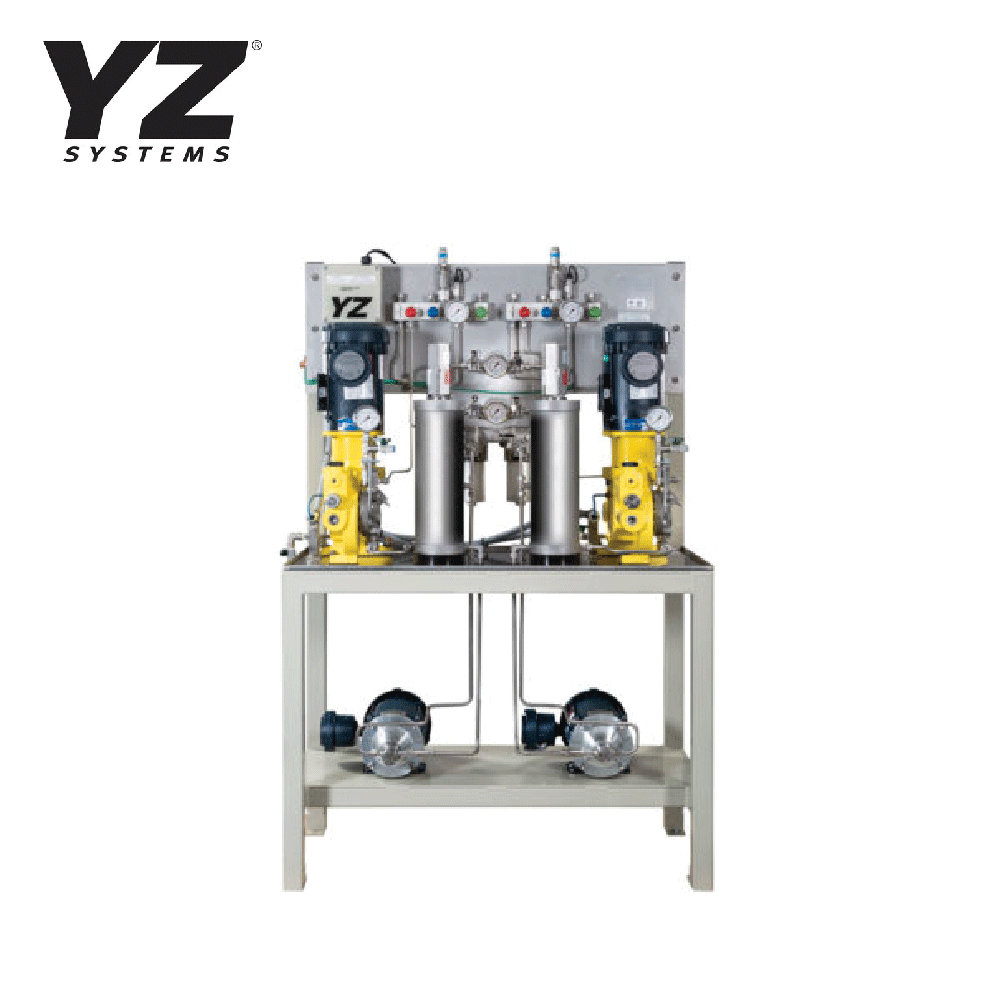

HVO ODORANT INJECTION SYSTEM

DESCRIPTION

The HVO High Volume Odorizer is designed for ultra-high accuracy and precision high volume injection. HVO injects at a customer-specified rate while automatically adjusting to changes in process flow rates and pump variability. HVO Features a large touch-screen interface with multiple layers and trend graphing, remote communication for seamless integration, and includes more than 25 customer adjustable parameters.

FEATURES

>> Zero emission design

>> Standard platform

>> Closed loop prime and purge

>> Auto compensating

>> Graphs, trends, reports

>> Auto switchover to backup in case of system alarm

SPECIFICATION

>> Capacity : 11.4 GPH (per pump) @ 1500 psi

>> Double diaphragm design eliminates unscheduled repairs

>> 316 SS head, hydraulically actuated diaphragm

>> 1/2 horsepower, explosion-proof motor

DOWNLOAD DOCUMENT

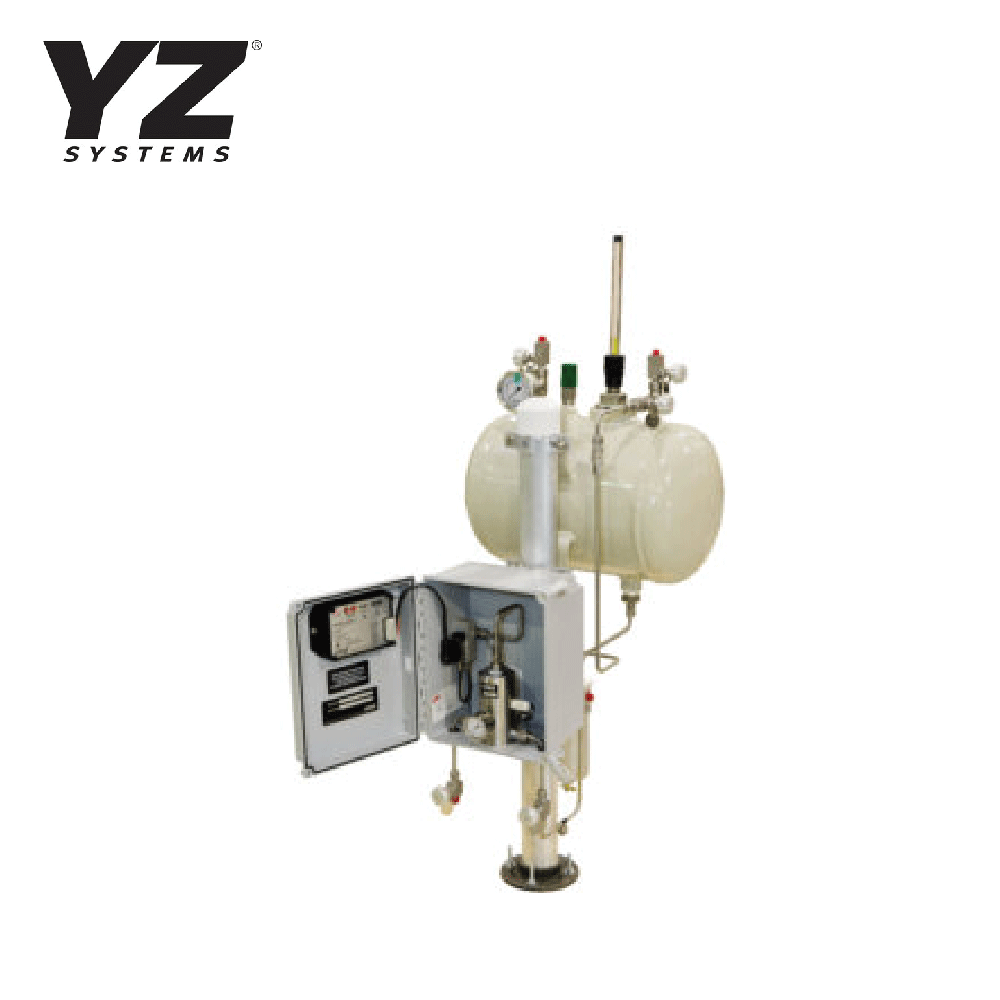

NJEX LOW VOLUME ORORIZER

DESCRIPTION

The NJEX low volume odorizer delivers reliability to low flow odorization applications. Its unique design delivers accuracy, reliability and odor-free performance and it eliminates the risk for “vapor locking” at even the lowest of flow rates. The system provides three levels of verification to confirm only the desired amount of odorant is introduced into the pipeline.

FEATURES

>> Patented pump design

>> Odor free operation

>> Three levels of verification

>> Technical support 24/7/365

>> Modular design for ease of maintenance

SPECIFICATION

>> Maximum odorant output : .38 gallons/day, 1.44 liters/day

>> Operating temperature : 0°-140°F, 17°C-60°C

>> 316 SS head, hydraulically actuated diaphragm

>> Power supply : LBP-14 battery

>> Gas flow input signal : pulse (dry contact or voltage)

DOWNLOAD DOCUMENT

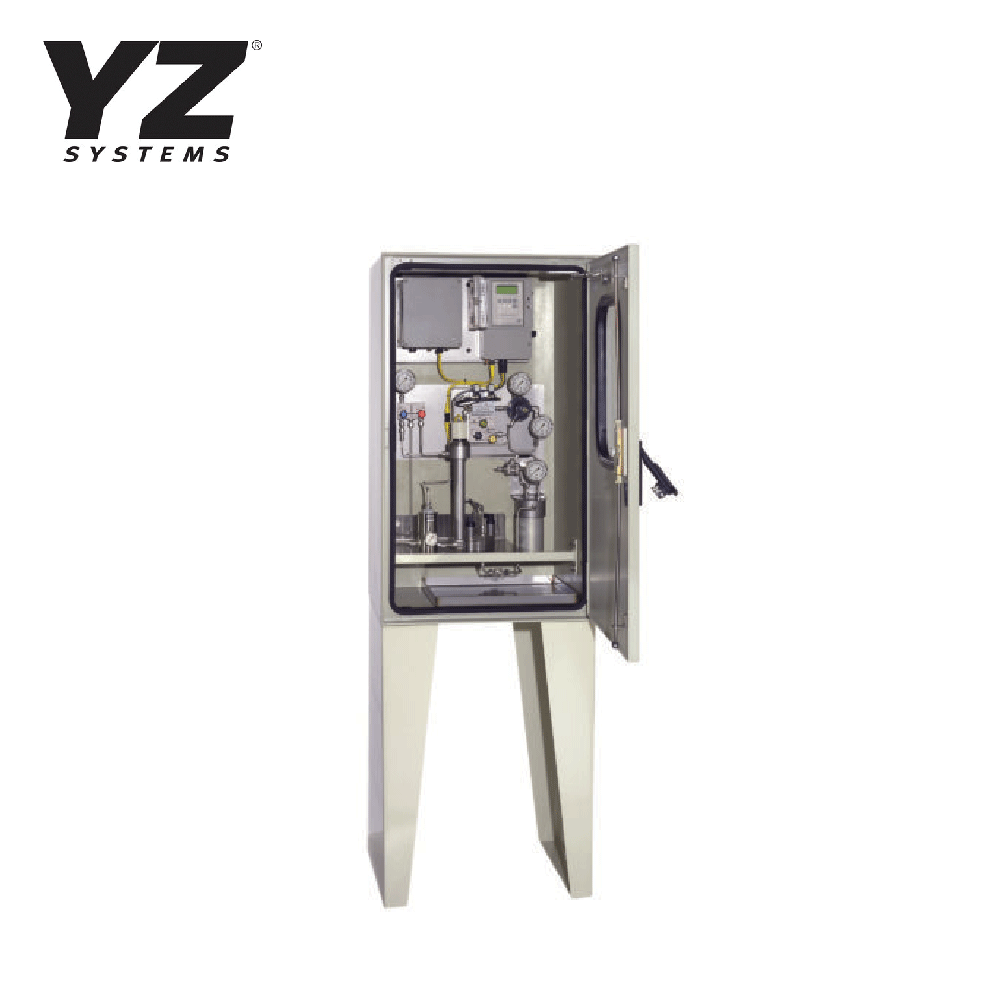

NJEX 6300 ODORANT INJECTION SYSTEM

DESCRIPTION

The 6300 is ideal for lower flow applications where accurate injection and performance verification is expected. This proven system reliably provides proportional-to-flow odorant injection, onboard metering of the odorant injected, system monitoring and alarm notification. Additionally the system will document and verify injection rates, performance of each system component, parameter changes and alarms.

FEATURES

>> Natural gas or liquid applicaitons

>> Odor free operation

>> Closed loop prime and purge

>> Standardized design

>> Remote communication via ModBus or Sentry4 software

>> Dedicated alarm systems

SPECIFICATION

>> Maximum odorant output : 1.76 gallons/day, 6.7 liters/day

>> Maximum operating pressure : 1440 psig, 99.28 bar

>> Operating temperature : 0°-140°F, 17°C-60°C (Heated options available for cold weather)

>> Power supply : solar or 120/240 volt, 50/60Hz AC

>> Battery reserve : approximately 30 days

>> Gas flow input signal : pulse (dry contact or voltage)

DOWNLOAD DOCUMENT

NJEX 7300 ODORANT INJECTION SYSTEM

DESCRIPTION

The 7300 Series was the first system in the NJEX family and remains the industry flagship for most user applications. This mid-use, primary odorizer provides proportional-to-flow odorant injection, onboard metering of the odorant injected, system monitoring and alarm notification. Additionally the system will document and verify the performance of each system component, parameter changes, alarms and injection rates.

FEATURES

>> Natural gas or liquid applicaitons

>> Odor free operation

>> Closed loop prime and purge

>> Standardized design

>> Remote communication via ModBus or Sentry4 software

>> Dedicated alarm systems

SPECIFICATION

>> Maximum odorant output: 17.6 gallons/day, 67 liters/day

>> Maximum operating pressure: 1440 psig, 99.28 bar

>> Operating temperature: 0°-140°F, 17°C-60°C (Heated options available for cold weather)

>> Power supply: solar or 120/240 volt, 50/60Hz AC

>> Battery reserve: approximately 30 days

>> Gas flow input signal: pulse (dry contact or voltage)

DOWNLOAD DOCUMENT

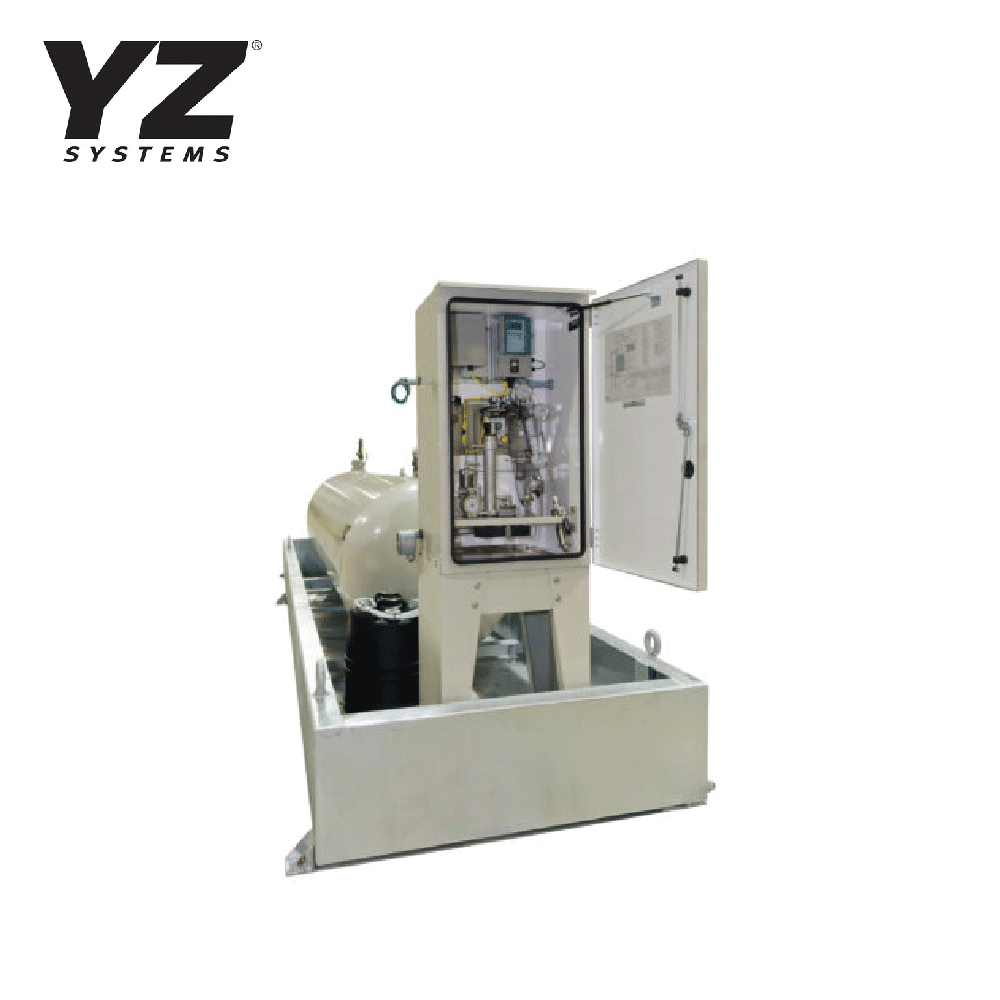

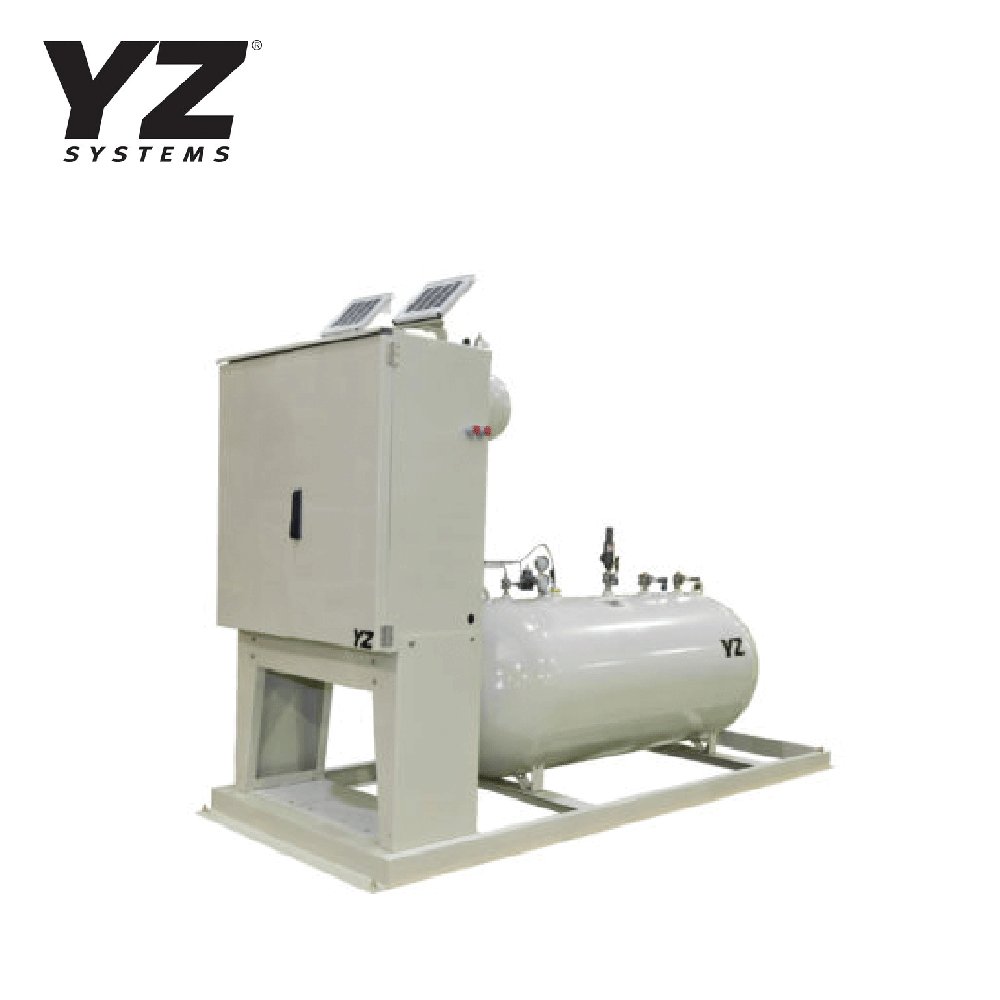

NJEX 8300 ODORANT INJECTION SYSTEM

DESCRIPTION

The 8300 is designed for high volume injection applications. The dual configuration (8302) will accurately inject up to 136 gallons per day. This system has provided reliable performance at critical injection points worldwide for many years. This proven system reliably provides proportional-to-flow odorant injection, onboard metering of the odorant injected, system monitoring and alarm notification. Additionally, the system will document and verify injection rates, performance of each system component, parameter changes and alarms.

FEATURES

>> Natural gas or liquid applications

>> Odor free operation

>> Closed loop prime and purge

>> Standardized design

>> Remote communication via ModBus or Sentry4 software

>> Dedicated alarm systems

SPECIFICATION

>> Maximum odorant output: 68 gallons/day, 257 liters/day

>> Maximum operating pressure: 1440 psig, 99.28 bar

>> Operating temperature: 0°-140°F, 17°C-60°C (Heated options available for cold weather)

>> Power supply: solar or 120/240 volt, 50/60Hz AC

>> Battery reserve: approximately 30 days

>> Gas flow input signal: pulse (dry contact or voltage)