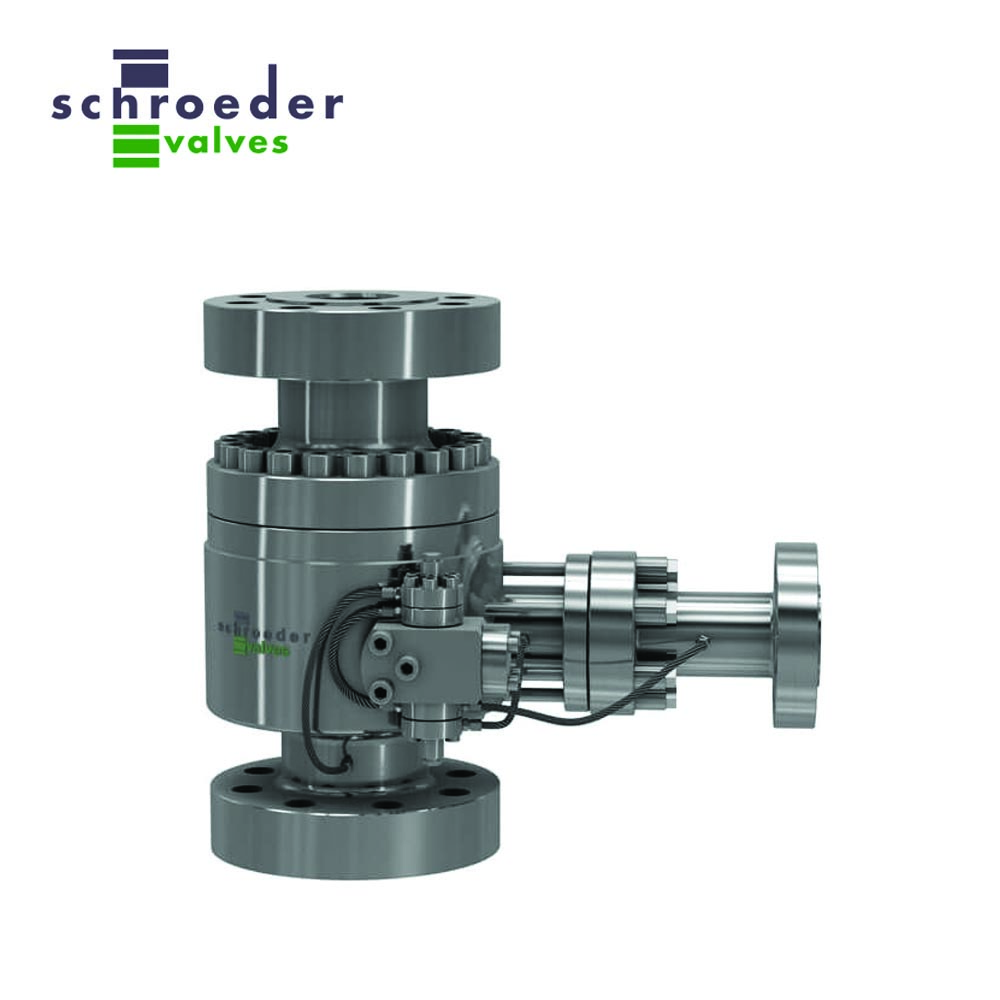

SCHROEDER VALVES THE SHP SERIES

DESCRIPTION

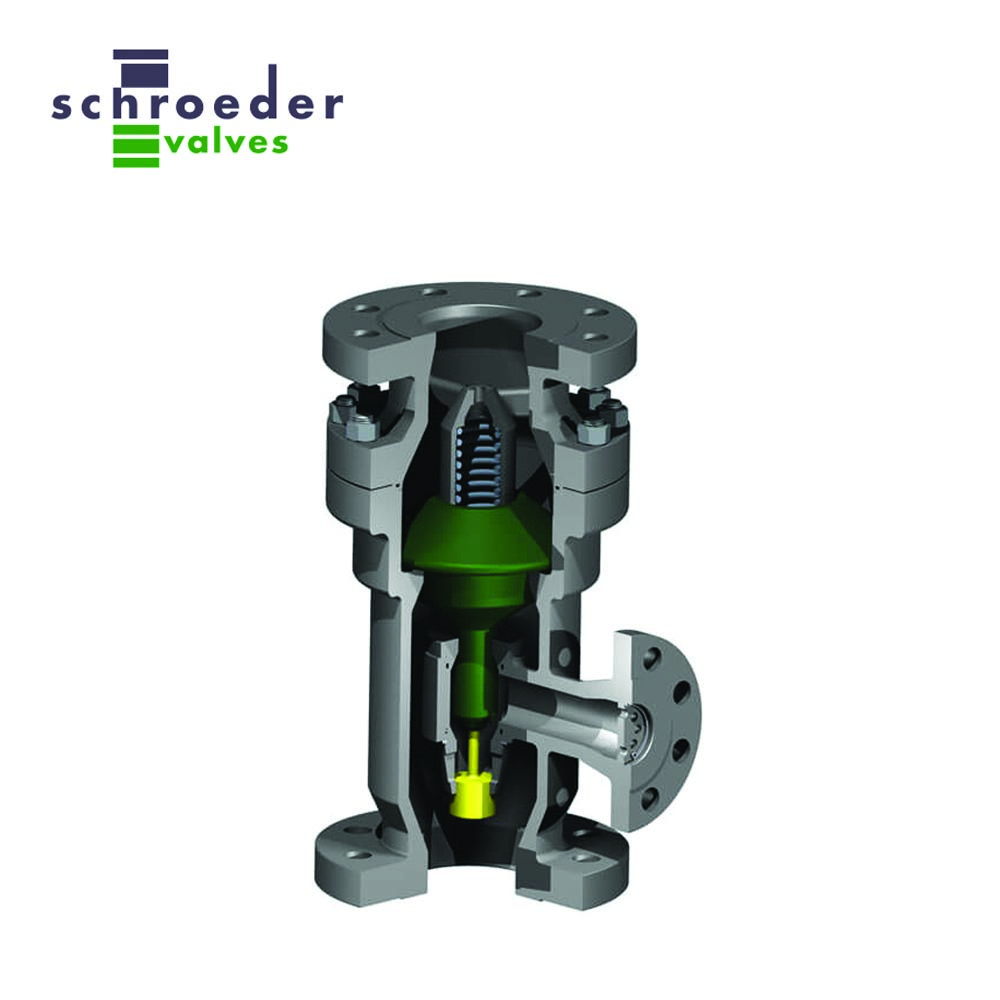

The SHP series automatic recirculation valve protects pumps and equipment from damage that can occur due to the flow rate falling below the permissible minimum. The innovative design ensures that pumps and equipment are reliably protected, even in situations involving highly fluctuating pump loads and long periods of operation under extreme partial load conditions. This is achieved using a special fully automatic minimum flow control system that ensures the release of a modulating adaptive minimum flow. In addition, the wear-intensive extreme partial load range is deliberately overridden. The shut-off and pressure reduction functions are both functionally and physically separate from each other. This makes the SHP Series the ideal fitting for applications involving very flexible operating conditions, such as those commonly found in modern power plants, for example.

FEATURES

>> low-wear continuous operation

>> high and maximum pressure range

>> all conceivable load conditions

>> low pressure loss

>> continuous control response with deliberate overriding of high-wear

>> extreme partial load range

>> high energy efficiency

>> operational safety, reliability, low maintenance

>> long service life

>> automatic regulation of the pump’s minimum required flow rate

>> modulating bypass flow control

DOWNLOAD DOCUMENT

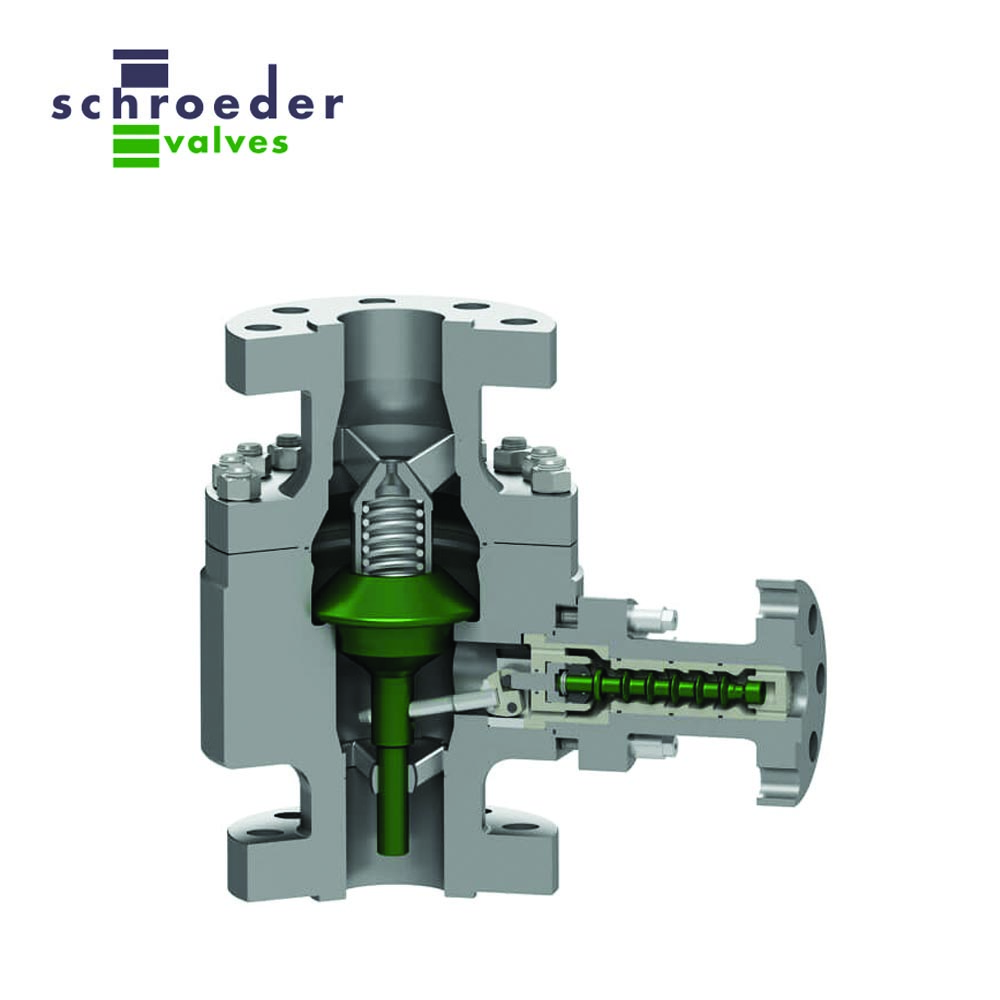

SCHROEDER VALVES THE SIP SERIES

DESCRIPTION

The minimum flow valves from our SIP series is the ideal valve for applications with pressures between 140 and 250 bar in systems with continuous operation, even at load points below the pump minimum quantity. The SIP controls the bypass by means of a multi-stage piston, which enables a defined multi-stage pressure reduction for all flow rates and also guarantees cavitation-free operation at all times. The piston of the SIP is actuated directly by the plug via a lever; the pressure is balanced to reduce the actuating forces. By means of pressure compensation, the actuating forces are reduced to such an extent that a pilot system (as with the SMA /SHP high-pressure series) is not required. With its properties, the SIP is particularly suitable for the protection of boiler feed pumps in combined cycle power plants (CCPP).

FEATURES

>> low-wear continuous operation

>> for pressures between 140 and 250 bar

>> automatic regulation of the pump’s minimum required flow rate

>> Integrated non-return check valve function in the main and minimum flow line

>> reduced flow rate at the operating point due to automatic closing of the

>> minimum flow line and thus

>> lower drive/motor power of the pump

>> more favourable energy balance, more favourable plant costs

>> operational safety, reliability, low maintenance

>> long life

DOWNLOAD DOCUMENT

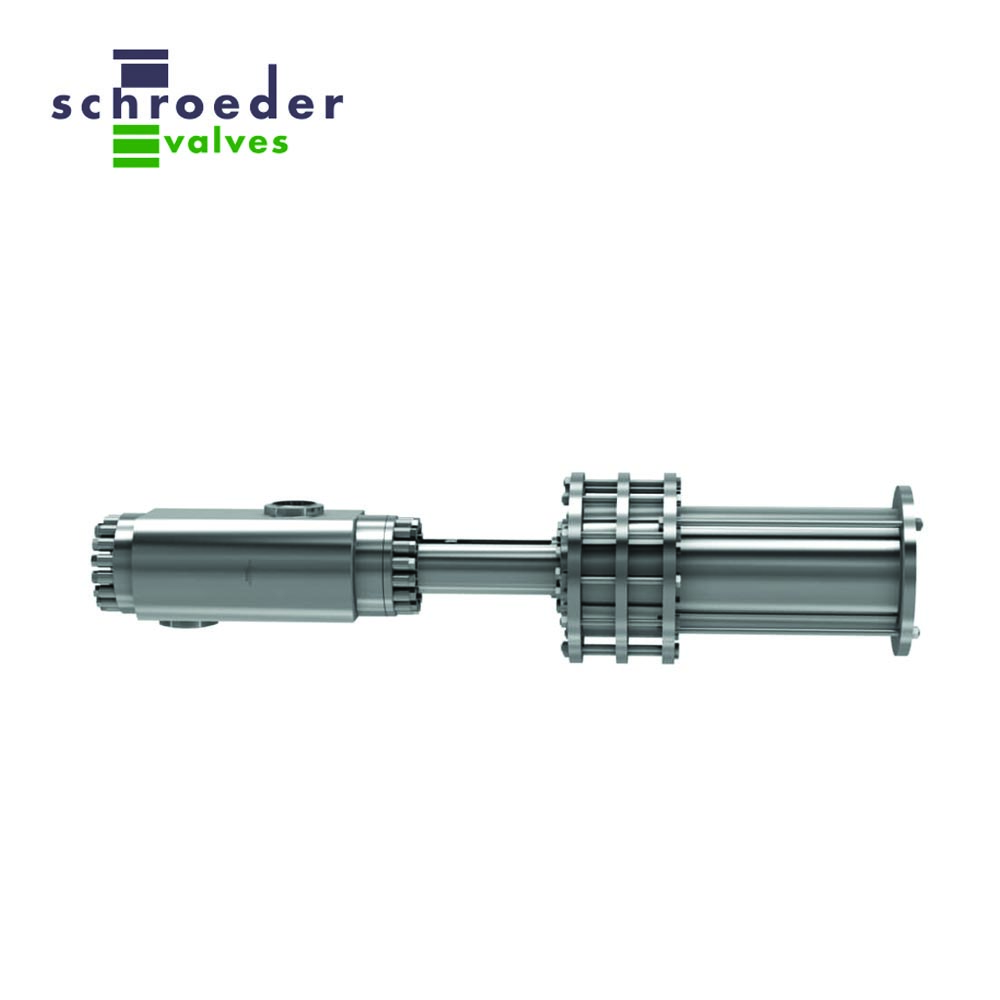

SCHROEDER VALVES THE SSV SERIES

DESCRIPTION

The automatic recirculation control (AR) valves from our SSV series automatically protect centrifugal pumps against wear, total loss and damage, which can occur due to dry running or during low-load operation. Our recirculation valves have historically proven exceptional reliability and low pressure loss over time. They are not susceptible to interference and are very low maintenance. In addition, they require no additional power supply or any kind of control unit, thus ensuring low operating costs.

FEATURES

>> Modulating and low-wear minimum volume controls as a result of the rotary valve design

>> Non return check-valve function in the main line prevents pump damage by back flow from the process line at shut-off and standby

>> Multi-level pressure and volume reduction in the secondary outlet ensures low cavitation levels

>> Self-actuated – no additional energy supply or measuring technology required

>> Low pressure losses

>> Vertical or horizontal installation

>> Internal components made of stainless steel

>> Reliable, with a long service life

DOWNLOAD DOCUMENT

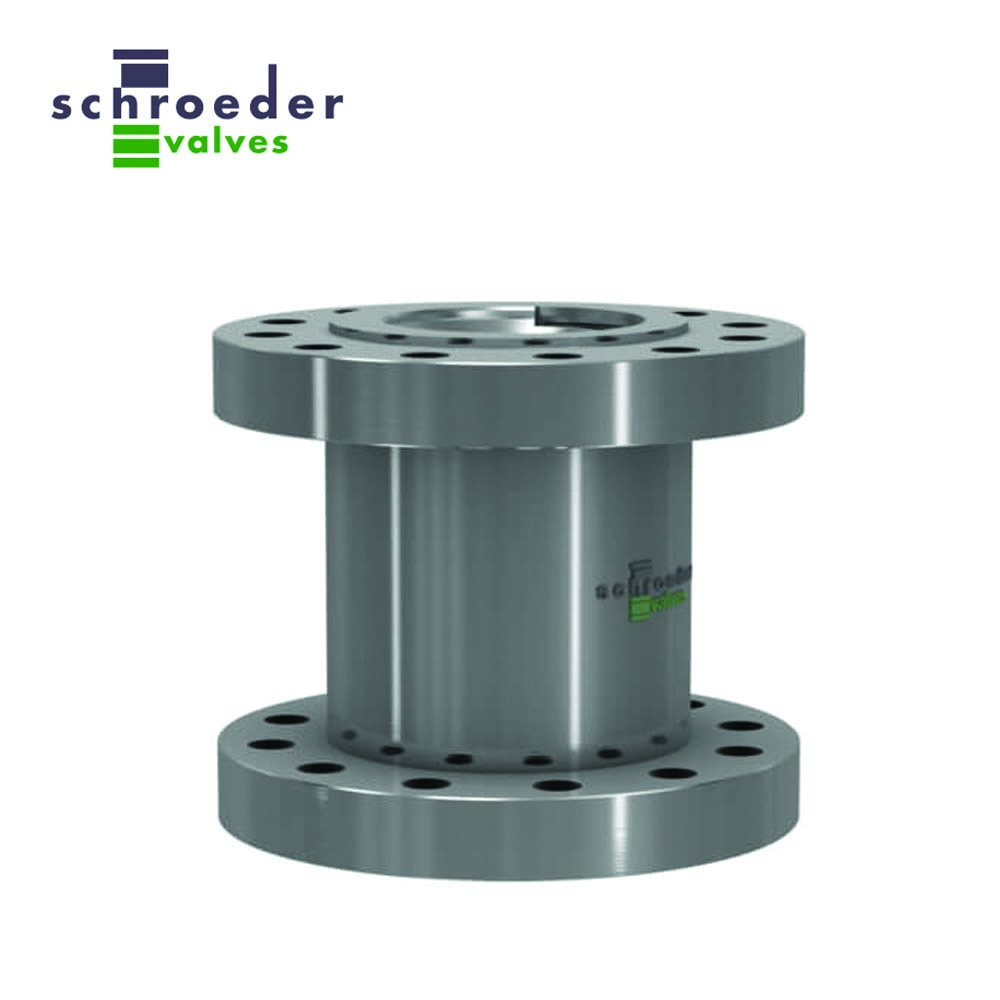

SCHROEDER VALVES THE SMV SERIES

DESCRIPTION

The Schroeder SMV series multi-functional valve is an automatic recirculation valve that is equipped with an automatic venting nozzle in addition to the minimum flow control and non-return device in the main feed. It permanently ensures that the stationary pump and standby pump are automatically vented and thus remain filled with liquid at all times.

FEATURES

>> Max DP of 250 bar

>> Self acting – controlled by medium (no external power)

>> No special maintenance

>> Degasification branch

>> Bypass throttle

>> Bypass non-return valve

DOWNLOAD DOCUMENT

SCHROEDER VALVES THE SMA SERIES

DESCRIPTION

The SMA 63/64 automatic minimum flow system is a protective pump fitting. It automatically protects centrifugal pumps against damage that may occur as a result of the partial evaporation of the pump content when the pumps are operated under low load. As soon as the main pump flow falls below a predetermined value, the valve opens the bypass and safely drains the minimum volume, even if the pumping volume in the main flow direction drops to zero.

The bypass is always completely opened or closed through its pilot-controlled valve piston (15/for illustration, see page 3 of SMA 63). This “ON/OFF” control makes it possible to increase the previous load limit of the valves from 200 bar to 400 bar (pumping pressure). The preferred utilization range is thus between PN 250 and PN 400 or ANSI CLASS 2500. The bypass amount may be up to 35% of the main pumping volume. The valve functions without an additional source of energy.

FEATURES

>> Max DP > 180 bar to 450 bar

>> Self acting – controlled by medium (no external power)

>> Built in check valve

>> No special maintenance

DOWNLOAD DOCUMENT

SCHROEDER VALVES THE SR/SA SERIES

DESCRIPTION

The SR/SA valve type has been designed to control liquid media at high and very high pressures. The control valve is able to safely withstand pressures up to 600 bar and media temperatures of up to 400 °C. It is suitable for use both as a stand-alone shut-off valve (type SA) as well as for flow-control (type SR). When used for pump protection, SR/SA valves are mainly used in modern process control and monitoring systems. They make it possible to accurately adjust the minimum volume regulation to our customers’ system requirements. The use of actuators and sensors allows the valve to be fully integrated in modern process technology. SR/SA valves therefore extend Schroeder’s product range to include control valves. They make a valuable contribution to low-energy, low-wearing pump operation.

FEATURES

>> can be fitted with all types of actuators (electric, pneumatic, hydraulic)

>> there is an intrinsic medium actuated version available for valves with “open/closed” functionality that works without the need for external power

>> the use of actuators and sensors allows the valve to be fully integrated in modern process technology

>> highly efficient minimum flow control that can be monitored or adjusted at any time via the process control system

DOWNLOAD DOCUMENT

SCHROEDER VALVES THE SSD SERIES

DESCRIPTION

The multiport throttles are used in nominal widths ranging from DN20 to DN500, in pressure steps up to PN640 and up to a permissible media temperature of 400°C. The throttle housings are normally made of 1.0460 (C22.8) steel suitable for pressurized vessels, but can also be made of various types of stainless steel, depending on the medium. Configuration takes place in accordance with the AD 2000/EN 13445 regulations. The products are CE-labeled in accordance with the DGR 97/23 EC directive on pressurized devices and a conformity statement is issued. All hazard groups in categories 1 to 4 are included in the certification according to Module H1 (DGR 97/23 EC).

FEATURES

>> Pressure & flow reduction

>> Carbon steel / Stainless SteelOther materials on request

>> Forged stainless steel / Hardfaced / Stellited

>> Used to reduce the pressure and flow rate of fluids in pipe systems.

DOWNLOAD DOCUMENT

SCHROEDER VALVES THE SDV SERIES

DESCRIPTION

The active principle of the SDV is based on a spring-loaded locking cone. The cone and spring are coordinated in such a way that once the specified holding pressure has been reached, the pressure force is sufficient to lift the cone out of its seat, thus permitting flow. Unlike conventional back pressure devices / counter-pressure regulators, the cone of our back pressure device has been equipped with a control profile. This allows the throttle surface at the cone seat to accurately adapt to the relevant flow rate, thereby minimizing the unfortunate tendency of spring-loaded locking devices to produce knocking or hammering noises at low flow rates. The SDV is therefore suitable for systems with a wide operating range and frequent partial load operation.

FEATURES

>> Back pressure control

>> Integrated non return valve

>> Carbon steel / Stainless SteelOther materials on request

>> Forged stainless steel / Hardfaced / Stellited

>> Keeps the static pressure within a pipeline above a defined minimum value to avoid cavitation and partial evaporation

DOWNLOAD DOCUMENT

SCHROEDER VALVES SMARTLINE VALVE

DESCRIPTION

Our product range, smartline, is an automatic recirculation valve for the protection of standard centrifugal pumps. The valves of the smartline range automatically protect the pumps against wear, total failure and damage caused by dry running or during low-load operation. The smartline valves are available in various sizes, all of which are located in the low-pressure range. They are suitable for various media and for admissible average medium temperatures between -50°C and 200°C.

FEATURES

>> Valve size: 2“-6“

>> Valve rating: class 150/300

>> Connection: flange ASME B16.5 RF

>> Body material: A351CF8, stainless steel

>> 2-piece body design

>> Internal parts: stainless steel

>> Main flow Q100 :15 m3/h – 580 m3/h

>> Suitable for a large range of different media

>> Admissible medium temperature: from -50°C to 200°C

>> Sizing and selection according to defined and fixed staggered design-matrix for body and internal parts

>> Automatic bypass flow control

>> Orifice plate

>> Integrated check valve function for main flow