STAND-OFF ALUMINUM ANODE WITH COW HORN TUBULAR INSERT

DESCRIPTION

DOWNLOAD DOCUMENT

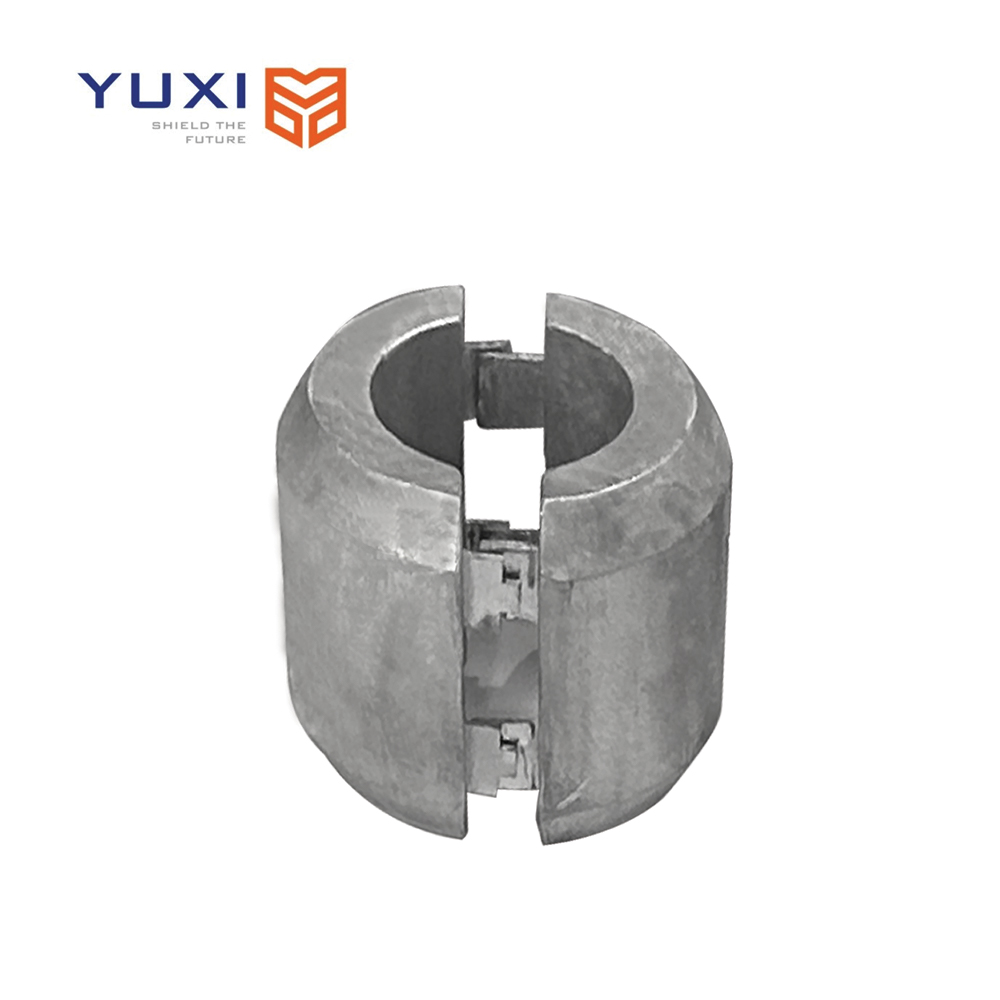

HALF SHELL ALUMINUM BRACELET ANODE (TAPERED END, WELDED)

DESCRIPTION

DOWNLOAD DOCUMENT

HIGH SILICON CAST IRON ANODES

DESCRIPTION

High silicon cast iron anodes are amongst the most widely used anodes for impressed current cathodic protection systems. Due to its high content of silicon, the anode surface is readily and continually oxidized with a thin film of hydrated silicon oxides, which protects the anode from metal pitting. Our high silicon cast iron anodes exhibit extraordinary corrosion resistance and low consumption rate in low-pH environment. They have been used for many decades to protect buried and submerged structures from corrosion, such as vertical deepwell, groundbed trench, offshore oil drilling platforms, etc. We developed rigid controls for the chill casting process in accordance with the highest standards —

meeting X-Ray Level 1 as per ASTM E186/E446, chemistry to either ASTM A518-99 Gr 1 or 3. ASTM A518 Grade 3 chemistry is particularly suited for more severe environments(such as brackish water or saltwater), where the level of chromium is elevated to enhance anode performance.