BEL Valves, part of the British Engines Group, was established in Newcastle-Upon-Tyne in 1964 to design and manufacture high pressure and high temperature valves for the petrochemical industry. In the 1970s, BEL Valves established itself as a key global supplier to the oil and gas industry. Today, we continue to lead the way in innovative engineering and customer service by pushing industry standards forward in safety, reliability and sustainability.

BEL Valves’ designs, manufactures and maintains high integrity valves, actuators and controls for subsea, surface and onshore applications. Our in-house teams support every customer from product design to aftermarket service providing a single source of supply. We have the knowledge and expertise to pioneer, innovate and develop the future of valve technology.

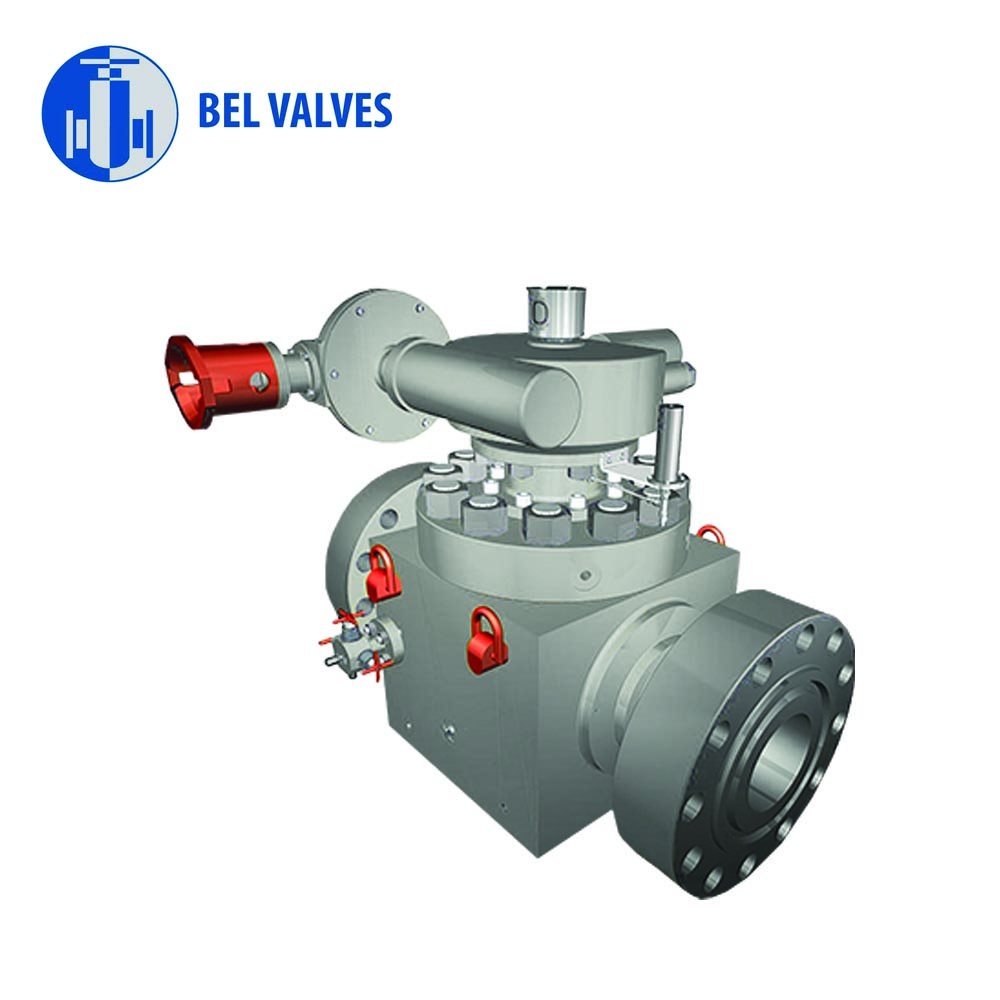

SUBSEA BALL VALVES

DESCRIPTION

Often deemed the optimum solution across subsea production system applications due to the naturally compact design, BEL Valves has over 20 years of experience in developing, qualifying and supplying subsea Ball Valves around the world to the most extreme operating conditions.

FEATURES

>> Bi-directional sealing

>> Double block and bleed (DBB)

>> Forged body

>> Metal-to-metal and soft sealing

>> Tungsten carbide hard facing

>> On-off

SPECIFICATIONS

>> Pressure rating : ANSI 150 to 2,500 and API 2,000 to 15,000 psi

>> Water depth : To 4,500m

>> Bore sizes : 1 ½” to 36”+

>> Material options Carbon and low alloy steel, stainless steel, duplex, super duplex and super alloys

>> Actuation Manual, ROV, hydraulic (FSC, FAI, FSO), electric

>> Standards API 6A and ISO 10423, API 6D SS and ISO 14723, API 17D and ISO 13628-4 and API 6AV1

DOWNLOAD DOCUMENT

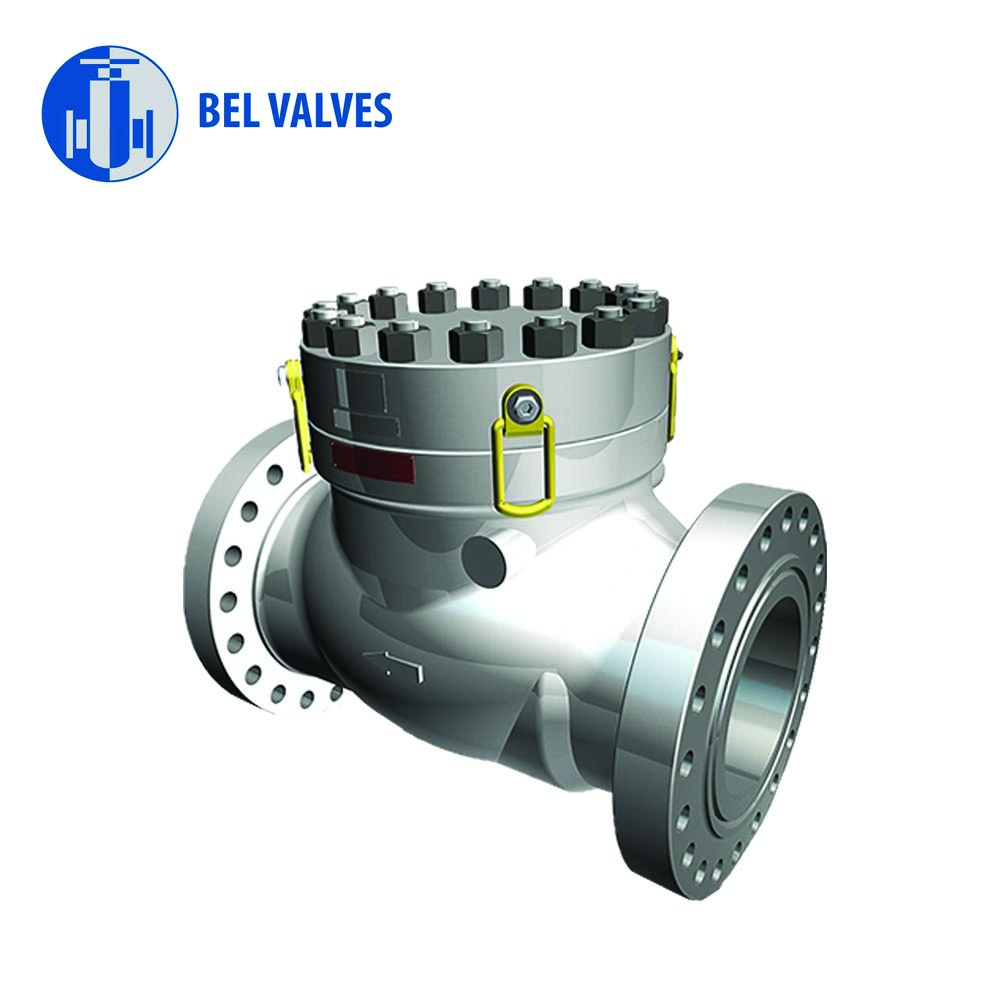

SUBSEA CHECK VALVES

DESCRIPTION

BEL Valves’ Check Valve range supports client needs for a flexible approach to solutions where protection against backflow and pressure surges are concerned. The robust design of the Swing Check Valve is typically favoured to overcome these service conditions on large bore applications, whereas the Axial and Piston Check Valve products provide assurance where more compact design is demanded.

FEATURES

>> Non-return

>> Metal-to-metal sealing

SPECIFICATIONS

>> Pressure rating : ANSI 150 to 4,500 API 2,000 to 20,000 psi

>> Water depth : 4,500 m

>> Bore sizes : ½” to 42”

>> Material options : Carbon and low alloy steel, stainless steel, duplex, super duplex and super alloys

>> Typical standards : API 6A and ISO 10423, API 6D and ISO 14313

DOWNLOAD DOCUMENT

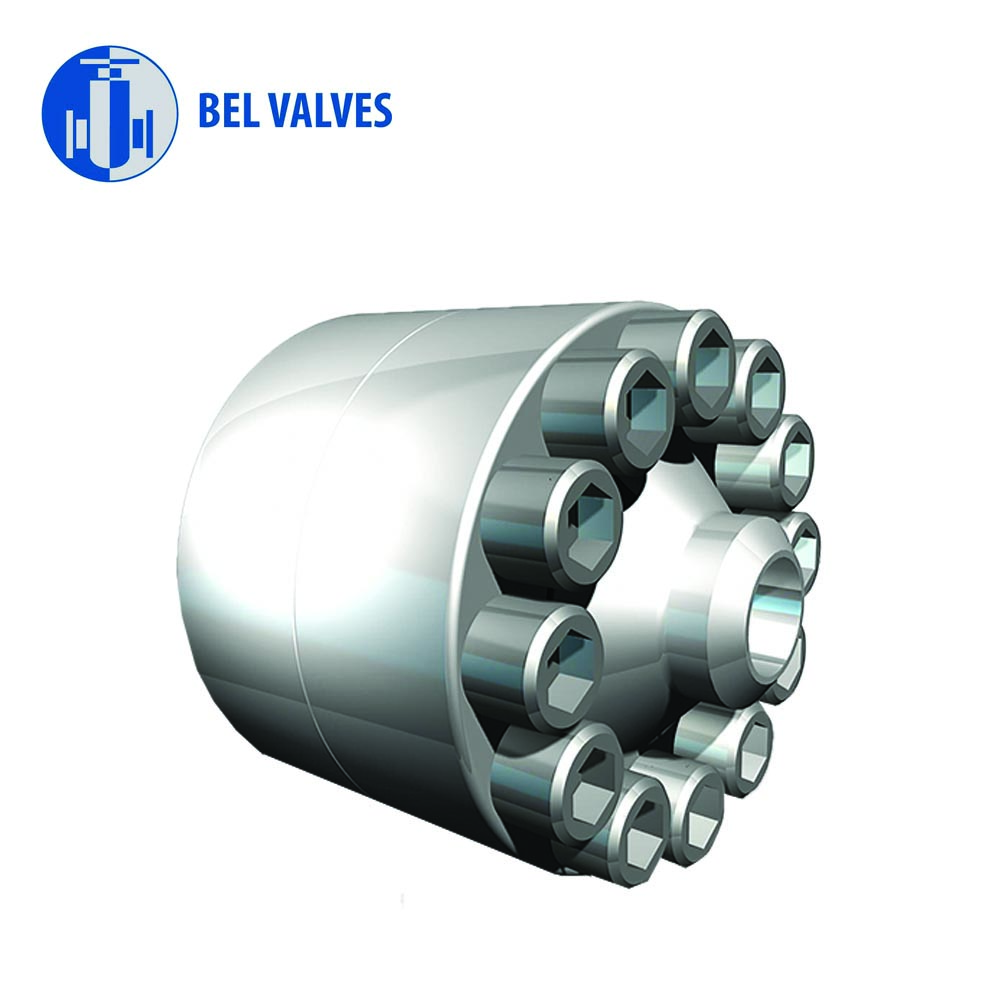

THROUGH CONDUIT EXPANDING GATE VALVE

DESCRIPTION

BEL Valves’ Through Conduit Expanding Gate Valve enables double block and bleed functionality to be achieved within one single valve assembly as opposed to the two conventional slab gates that would otherwise be required. The benefits include an overall cost, size and weight reduction in addition to an ability to configure the valve to seal in either the closed position (single expanding) or open and closed position (double expanding).

FEATURES

>> Metal-to-metal sealing

>> On-off

>> Rising stem (outside screw)

>> Tungsten carbide hard facing

SPECIFICATIONS

>> Pressure rating : ANSI 150 to 2,500 and API 2,000 to 20,000 psi

>> Temperature : -100˚c to +190˚c

>> Water depth : To 4,500m

>> Bore sizes : ½” to 32”

>> Material options : Carbon steel, low alloy steel, stainless steel, duplex, super duplex and inconel

>> Actuation : Manual, ROV, hydraulic (FSC, FAI, FSO), electric

>> Standards : API 6A, API 6D, API 6D SS, API 17D, API 6AV1, ISO 10423, ISO 13628, ISO 14313, ISO 14723

DOWNLOAD DOCUMENT

THROUGH CONDUIT SLAB GATE VALVE

DESCRIPTION

Supplying the first subsea Gate Valve in 1990, BEL Valves demonstrates a successful track record of product installation in shallow to ultra-deep waters around the world. The subsea Through Conduit Gate Valve continues to be designed in accordance with the exacting industry standards and company engineering principles that ensures fit for purpose solutions every time.

FEATURES

>> Metal-to-metal sealing

>> On-off

>> Tungsten carbide hard facing

SPECIFICATIONS

>> Pressure rating : ANSI 150 to 2,500 and API 2,000 to 15,000 psi

>> Temperature : -100˚c to +190˚c

>> Water depth : To 4,500m

>> Bore sizes : ½” to 56”

>> Material options : Carbon steel, low alloy steel, stainless

steel, duplex, super duplex and inconel

>> Actuation : Manual, ROV, hydraulic (FSC, FAI, FSO), electric

>> Standards : API 6A, API 6D, API 6D SS, API 17D, API 6AV1, ISO 10423, ISO 13628, ISO 14313, ISO 14723

DOWNLOAD DOCUMENT

SURFACE BALL VALVE

DESCRIPTION

Our flexibility towards delivering an optimised surface Ball Valve solution ensures that both client and governing industry requirements are always met, and allows for a fit for purpose final product to be delivered on time and within budget. Additionally the E-Ball Valve is a patented product that provides double block and bleed (DBB) functionality within a single valve.

FEATURES

>> Bi-directional sealing

>> On-off

SPECIFICATIONS

>> Pressure rating : ANSI 150 to 2,500 To 15,000 psi

>> Configurations : Fully welded, top or side entry

>> Bore sizes : 1 ½” to 56”

>> Material options : Carbon and low alloy steel, stainless steel, low temperature carbon steel, duplex, super duplex and super alloys

>> Actuation : Manual, ROV, hydraulic (FSC, FAI, FSO), pneumatic

>> Standards : API 6A and ISO 10423, API 6D and ISO

14313, API 6AV1

DOWNLOAD DOCUMENT

SURFACE BUTTERFLY VALVE

DESCRIPTION

The continued call for the expansion of the BEL Valves product range has led to the development of a high-performance butterfly valve range of products. Currently, in the design phase, BEL Valves aims to launch the Triple Offset Butterfly Valve during 2020.

FEATURES

>> On-off

>> Bi-directional sealing

>> Metal-to-metal sealing

SPECIFICATIONS

>> Pressure rating : ANSI 150 to 300 psi

>> Temperature : -46˚c to +538˚c

>> Bore sizes : 2” to 48”

>> Material options : Carbon and low alloy steel, stainless steel, low temperature carbon steel, duplex, super duplex, nickel, aluminium, bronze and titanium

>> Actuation : Manual, hydraulic, electric, pneumatic

>> Typical standards : API 607, API 609, API 598, BSEN 593, EN ISO 10497, ASME B16.34, EN ISO 5208

DOWNLOAD DOCUMENT

SURFACE CHECK VALVES

DESCRIPTION

BEL Valves’ Check Valve range supports client needs for a flexible approach to solutions where protection against backflow and pressure surges are concerned. The robust design of the Swing Check Valve is typically favoured to overcome these service conditions on large bore applications, whereas the Axial and Piston Check Valve products provide assurance where more compact design is demanded.

FEATURES

>> Non-return

>> Metal-to-metal sealing

SPECIFICATIONS

>> Pressure rating : ANSI 150 to 4,500 API 2,000 to 20,000 psi

>> Water depth : 4,500 m

>> Bore sizes : ½” to 42”

>> Material options : Carbon and low alloy steel, stainless steel, duplex, super duplex and super alloys

>> Typical standards : API 6A and ISO 10423, API 6D and ISO 14313

DOWNLOAD DOCUMENT

ONSHORE GLOBE VALVE

DESCRIPTION

At BEL Valves, our expertise allows us to deliver accurate and reliable Globe Valve solutions for specialist petrochemical applications for use in critical corrosive and hazardous applications including urea and ammonia production.

FEATURES

>> Steam jacket

SPECIFICATIONS

>> Pressure rating : API 2,000 to 30,000 psi

>> Bore sizes : ⅝” to 8”

>> Material options : Carbon and low alloy steel, stainless steel, duplex, super duplex and super alloys

>> Actuation : Manual, hydraulic, electric, pneumatic

>> Typical standards : API 6A and ISO 10423, API 6D and ISO 14313, ASME B16:34