Imperial Valve is a relatively young company and therefore has a short history. The company was founded in 1992 as a subsidiary of De Gidts & Feldman. The product range of Imperial Valve consist of double block & bleed valves, manifolds and instrument enclosures. Initially, the complete range of products of Imperial Valve was manufactured in Winsford, UK. Since 2004 the production has expanded considerably, and production sites are now situated in different locations in Europe. Over the years, Imperial Valve kept expanding and the company has gained a strong market position. In 2010 Imperial Valve B.V. started to form an international network of carefully selected distributors, to meet the growing demand for export. The international distributors are situated close to the customers, speaking their language and understanding their local challenges.

NEEDLE VALVES

DESCRIPTION

Bar stock needle valves are designed for operation up to 10,000 PSI rating. With standard PFTE stem packing & self centering non-rotating stem, our needle valves give in service total sealing security and easy manoeuvrability.

FEATURES

>> Tee bar easily maneuverable with minimum effort

>> PTFE packing standard, optional Grafoil

>> Stainless steel construction as standard

>> Externally adjustable gland

>> Variety of end connections

>> Dust cap to prevent contamination on the operating thread

SPECIFICATIONS

>> Pressure up to 10,000 PSI (690 Bar)

>> Temperature rating PFTE packing from -73°C to 210°C (-99°F / +410°F)

>> Temperature rating Grafoil packing from -54°C to +510°C (-65°F / +950°F)

>> Standard orifice diameter 4.0 mm

>> Standard 316L stainless steel (other materials available)

DOWNLOAD DOCUMENT

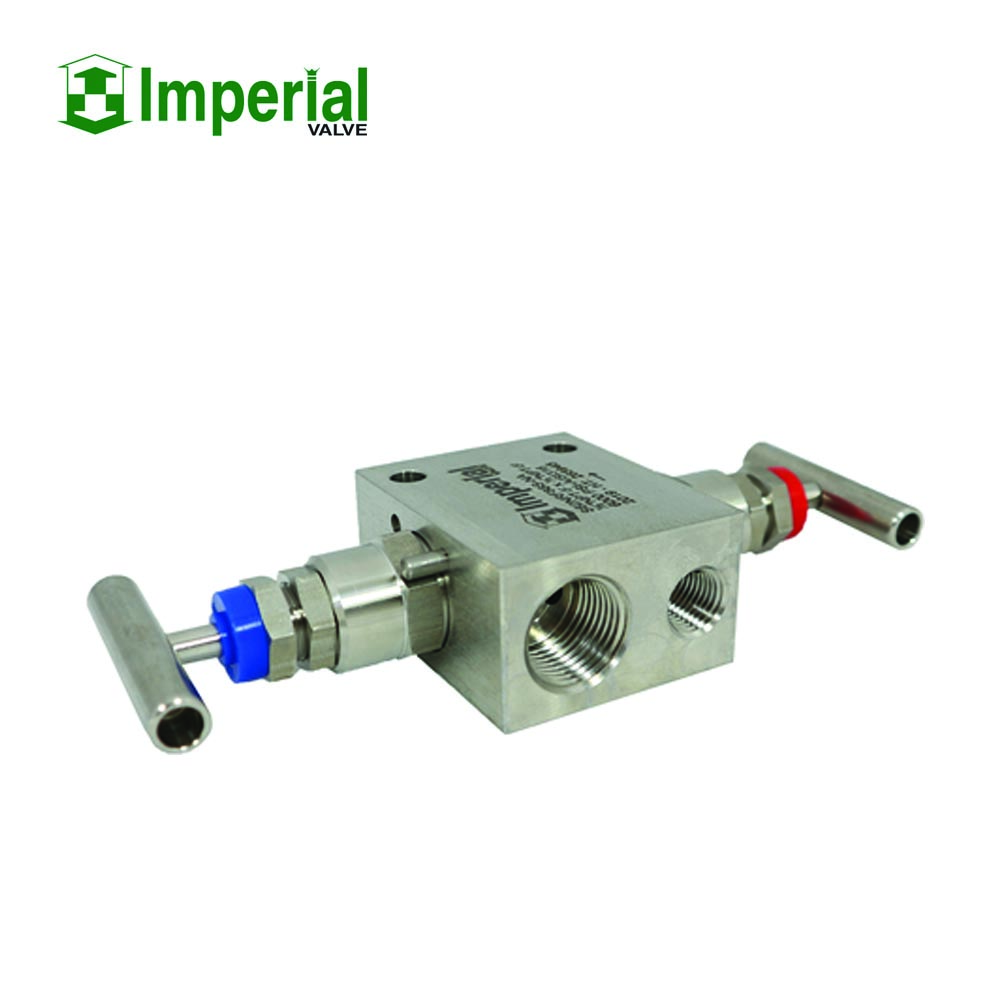

2 VALVE MANIFOLDS

DESCRIPTION

This series of 2 Valve Manifolds combines valves into one block to perform isolation, bleed and calibration of pressure transmitters, gauges and switches. Process, Instrument and Vent connections can be provided in a variety of sizes and threaded forms including NPT, BSPT and BSPP. Several models of brackets are supplied to realize the installation both on site and on panels.

FEATURES

>> Tee bar easy manoeuvrability with minimum effort

>> PFTE packing standard, optional Grafoil

>> Stainless steel construction as standard

>> Colour coded functional identification

>> Externally adjustable gland

>> Variety of end connections

>> Dust cap to prevent contaminations on the operating thread

SPECIFICATIONS

>> Pressure up to 10,000 PSI (690 Bar)

>> Temperature rating PFTE packing from -73°C to 210°C (99°F / +410°F)

>> Temperature rating Grafoil packing from -54°C to +510°C (-65°F / +950°F)

>> Standard orifice diameter 4.0 mm

>> Standard 316L stainless steel (other materials available)

DOWNLOAD DOCUMENT

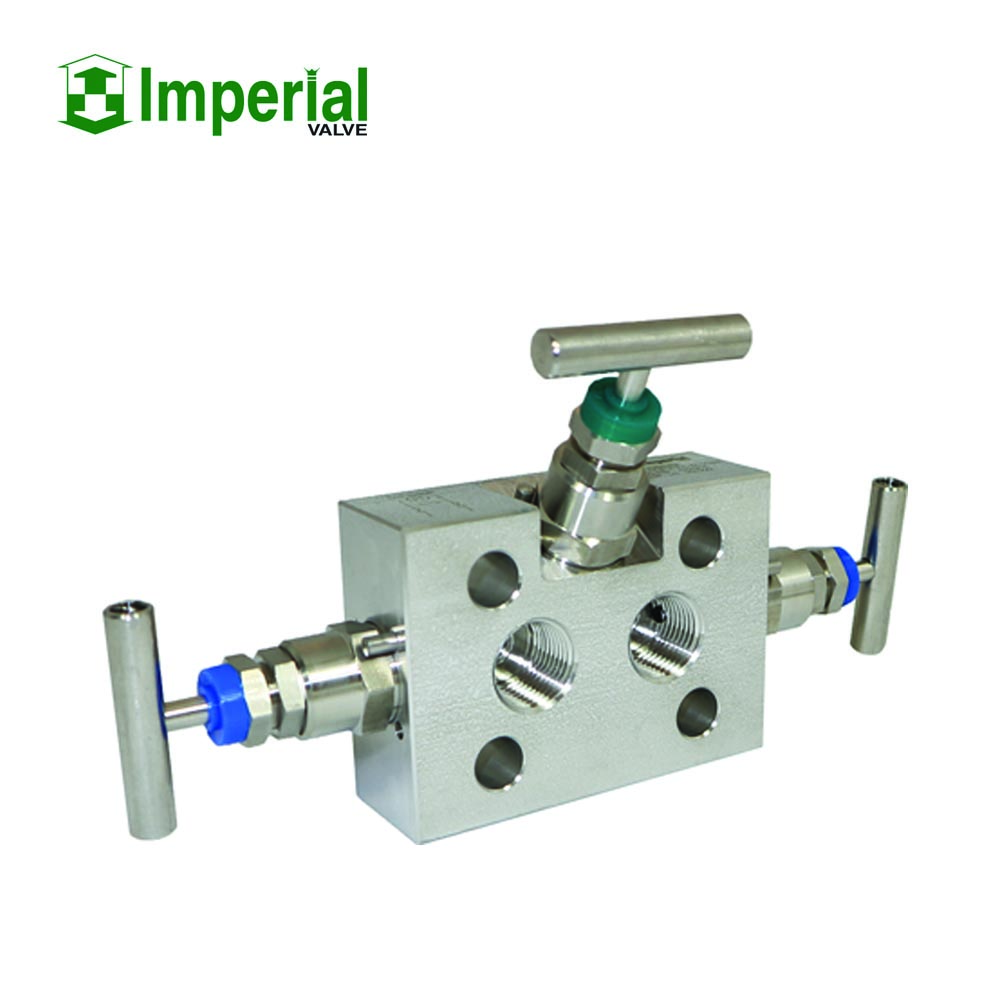

3 VALVE MANIFOLDS

DESCRIPTION

The 3 Valve Manifolds, that concentrate the functions of isolation and equalizing in a single block, are used with differential pressure transmitters and gauges. They are designed to allow both direct and remote mounting. Mounting brackets are available on demand.

FEATURES

>> Tee bar easy manoeuvrability with minimum effort

>> PFTE packing standard, optional Grafoil

>> Stainless steel construction as standard

>> Colour coded functional identification

>> Externally adjustable gland

>> Variety of end connections

>> Dust cap to prevent contaminations on the operating thread

SPECIFICATIONS

>> Pressure up to 10,000 PSI (960 Bar)

>> Temperature rating PFTE packing from -73°C to +210°C

>> Temperature rating Grafoil packing from -54°C to +510°C

>> Standard orifice diameter 4.0 mm

>> Standard 316L stainless steel (other materials available)

DOWNLOAD DOCUMENT

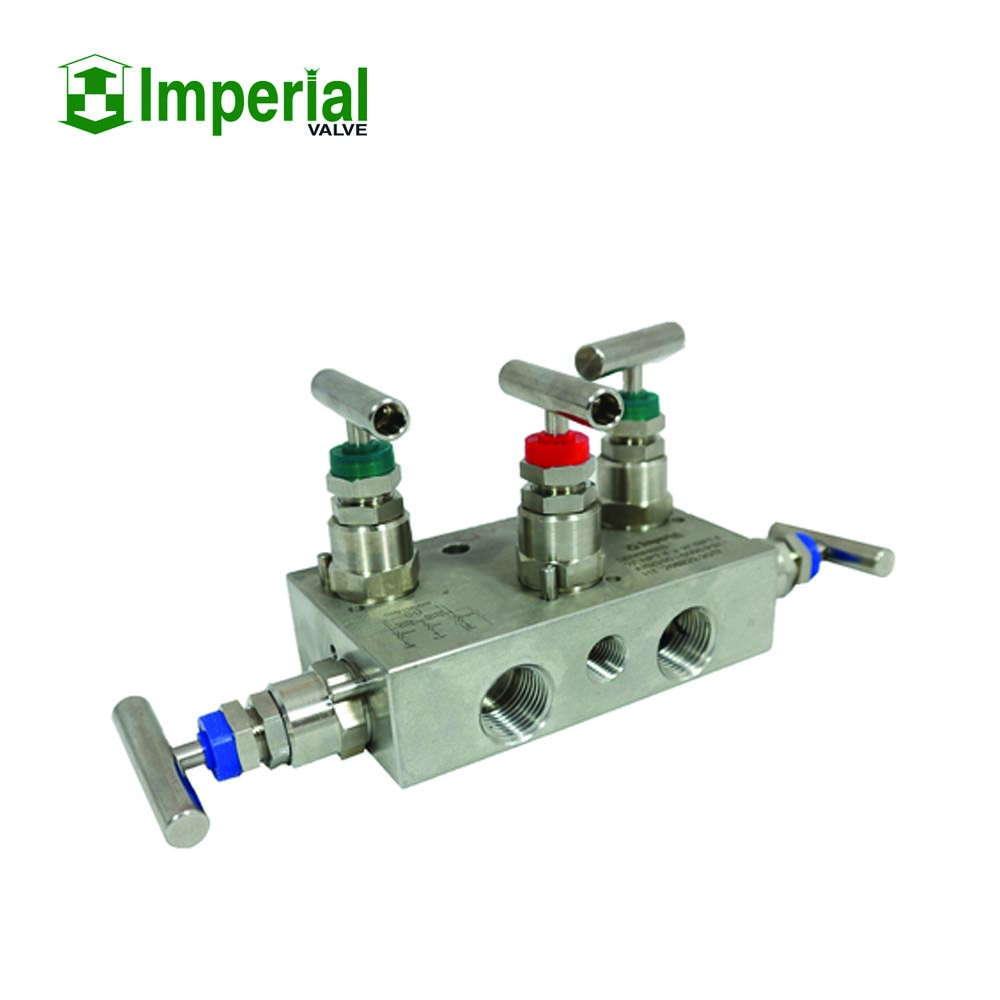

5 VALVE MANIFOLDS

DESCRIPTION

The 5 Valve Manifolds that concentrate in a single block the functions of isolation, equalise and vent are designed to allow both direct and remote mounting. Mounting brackets are available on demand.

FEATURES

>> Tee bar easy manoeuvrability with minimum effort

>> PFTE packing standard, optional Grafoil

>> Stainless steel construction as standard

>> Colour coded functional identification

>> Externally adjustable gland

>> Variety of end connections

>> Dust cap to prevent contaminations on the operating thread

SPECIFICATIONS

>> Pressure up to 10,000 PSI (690 Bar)

>> Temperature rating PFTE packing from -73°C to 210°C (99°F / +410°F)

>> Temperature rating Grafoil packing from -54°C to +510°C (-65°F / +950°F)

>> Standard orifice diameter 4.0 mm

>> Standard 316L stainless steel (other materials available)

DOWNLOAD DOCUMENT

BALL VALVES

DESCRIPTION

The three piece ball valves are designed to give higher strength and integrity by using the same dynamic multi-ring gland system as in the needle valve, which when combined with the anti-blowout back seating stem, guarantees resistance to all operating processes and pressures.

FEATURES

>> Super finished floating ball within dynamic, self relieving PEEK

>> PEEK packing standard

>> Stainless steel construction as standard (other materials available)

>> Flexible three piece construction for easy maintenance

>> Anti-blowout stem for safety

>> Variety of end connections

SPECIFICATIONS

>> Pressure up to 10,000 PSI (690 Bar)

>> Temperature rating PEEK packing from -40°C to 260°C (-40°F / +500°F)

>> Standard orifice diameter 10.0 mm

>> Standard 316L stainless steel

DOWNLOAD DOCUMENT

INSTRUMENT DOUBLE BLOCK & BLEED VALVES

DESCRIPTION

Where compactness and a high specification for mechanical and piping applications is required, Imperial Valve offers a complete range of instrument double block and bleed valves (dbb’s) in accordance with ANSI/ASME B.16.34. Variations of these instrument double block and bleed valves include sampling and chemical injection double block and bleed valves.

FEATURES

>> Through bore ball-needle-ball configuration

>> Reduced and full bore sizes available

>> Flange x thread or flange x flange configurations

>> Sampling and chemical injection versions available

>> Handle locking option available

>> Fire tested in accordance with BS6755 part II

SPECIFICATIONS

>> Flange sizes ½″ up to 3″ available

>> Ratings: ANSI 150-2500 lbs

>> Materials: wide selection of materials for both body and internals: carbon steel, low alloy steels, stainless steels, Duplex, Ni-alloys and titanium.

>> Including NACE MR-01-75 (latest revision)

DOWNLOAD DOCUMENT

PLUG VALVES, LARGE BORE

DESCRIPTION

Imperial Valve has introduced a new selection of large bore plug valves including double isolating plug valves. These valves are available with ANSI flanges, sizes 1″-24″, rating 150-2500 lbs.

FEATURES

>> Re-adjustable packing/plug

>> Optional actuators, gear boxes and extended handles

>> High-temperature applications available

>> Lubricated metal seated or soft seated

SPECIFICATIONS

>> Sizes: 2″-24″, ANSI flange possible

>> Ratings: ANSI 150-2500 lbs

>> Materials: a wide selection of materials for both body and internals: carbon steel, low alloy steels, stainless steels, Duplex, Ni-alloys and titanium

>> Including NACE MR-01-75 (latest revision)

DOWNLOAD DOCUMENT

DOUBLE BLOCK & BLEED MONOFLANGE

DESCRIPTION

The Double Block and Bleed Monoflange represents a true technical and economical innovation. Differently from the old system composed by big size block valves, safety and on-off valves, draining and sampling, these monoflanges allow to reduce costs and spaces. The monoflanges can be realized in traditional AISI 316 L as standard or exotic materials when required. They have compact dimensions with consequent reduction of assembling costs.

FEATURES

>> Rolled stem threads prevent galling

>> Stem threads are completely isolated from the process

>> Stem packing with graphite rings for bubble-tight seal

>> Bolted bonnet strength and reliability

>> Stem tip construction: non-rotating self-centering

>> Flange gasket seal ensures a bubble-tight between body and bonnet

>> Backseat design provides secondary stem sealing and prevents stem blowout

>> Adjustable gland flange allows easy access to the packing gland and packing adjustment for an effective stem seal

>> Robust handwheel painted

>> Firesafe to BS 6755 PART. 2

>> Pressure rating up to 6,000 PSI (413 bar)

>> Temperature rating: (Grafoil) -54°C / +510°C (-65°F / +950°F)