We provide engineered services and products primarily to the offshore energy industry. Today, we also use applied technology expertise to serve the defense, entertainment, material handling, aerospace, science, and renewable energy industries. We deliver industry-leading solutions for connecting critical service piping and vessel systems.

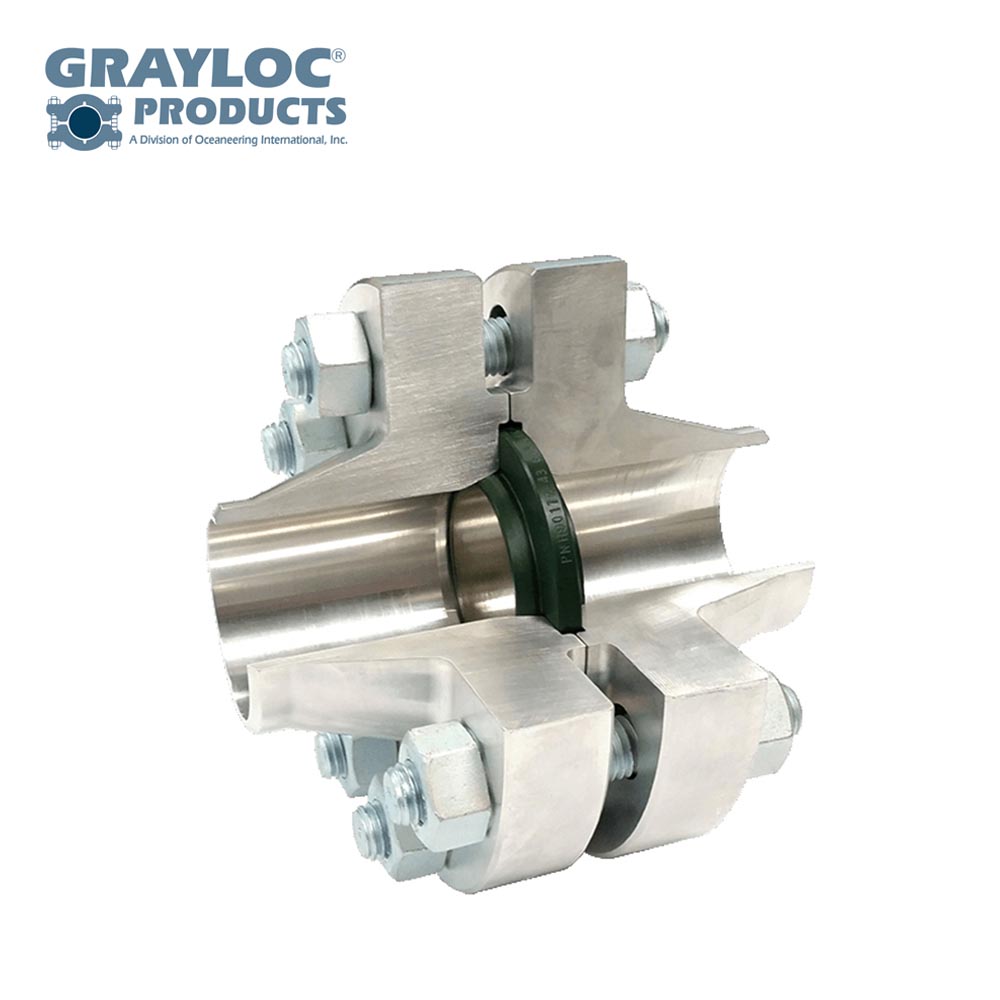

GRAYLOC® CLAMP CONNECTORS

DESCRIPTION

The Grayloc® Connector has been a fieldproven and reliable mechanical connector for over 50 years. This connector features a metal-to-metal bore seal that is recognized as the standard for critical service piping and vessel connections. Grayloc® connectors save weight, space, and fabrication time. Long after installation, ongoing advantages include lowered maintenance costs, reduced inventories, and increased performance.

DESIGN TECHNOLOGY

>> Grayloc® metal-to-metal seal

>> Self-energized and pressure-enhanced seal

>> Two-piece, four-bolt clamp design

>> Primary load-retaining member is the clamp, not the bolting

>> Significant space- and weight-saving design

>> Low makeup bolt torque

>> Visual indication of proper assembly

>> Reusable seal rings

BENEFITS

>> Eliminates fugitive emissions with zero-leakage seal (10-6 atm cc/s helium)

>> Reduces installation time with only four bolts and 360° clamp rotation

>> Simplifies fabrication (no bolt holes to align)

>> Lowers maintenance costs

>> Minimizes spare parts inventory

>> Enables design of lightweight and compact piping systems, using integral fitting configurations

>> Grayloc hub profiles can be integrated into third-party (OEM) products

DOWNLOAD DOCUMENT

GRAYLOC® COMPACT FLANGES

DESCRIPTION

Grayloc® compact flanges (GCFs) incorporate our proven metal-to-metal technology into a bolted flange design. Including the Grayloc seal ring in a compact flange design provides a solution with significant space and weight savings that outperforms conventional flanges.

DESIGN TECHNOLOGY

>> Grayloc® metal-to-metal seal

>> Self-energized and pressure-enhanced seal

>> Space and weight are less when compared to conventional flanges

>> Optimized bolting configurations

>> Engineered to industry standard design codes, including ASME and API

>> Visual indication of proper assembly

>> Reusable seal rings

BENEFITS

>> Eliminates fugitive emissions with zero leakage seal (10-6 atm cc/s helium)

>> Enables significant space and weight savings

>> Reduces installation time with smaller and fewer bolts

>> Lowers maintenance cost

>> Minimizes spare parts inventory

>> Eliminates mismatches common in male and female designs with standard seal interfaces

>> Enables design of lightweight and compact piping systems using integral fitting configurations

>> Enables integrating Grayloc hub profiles into third-party (OEM) products

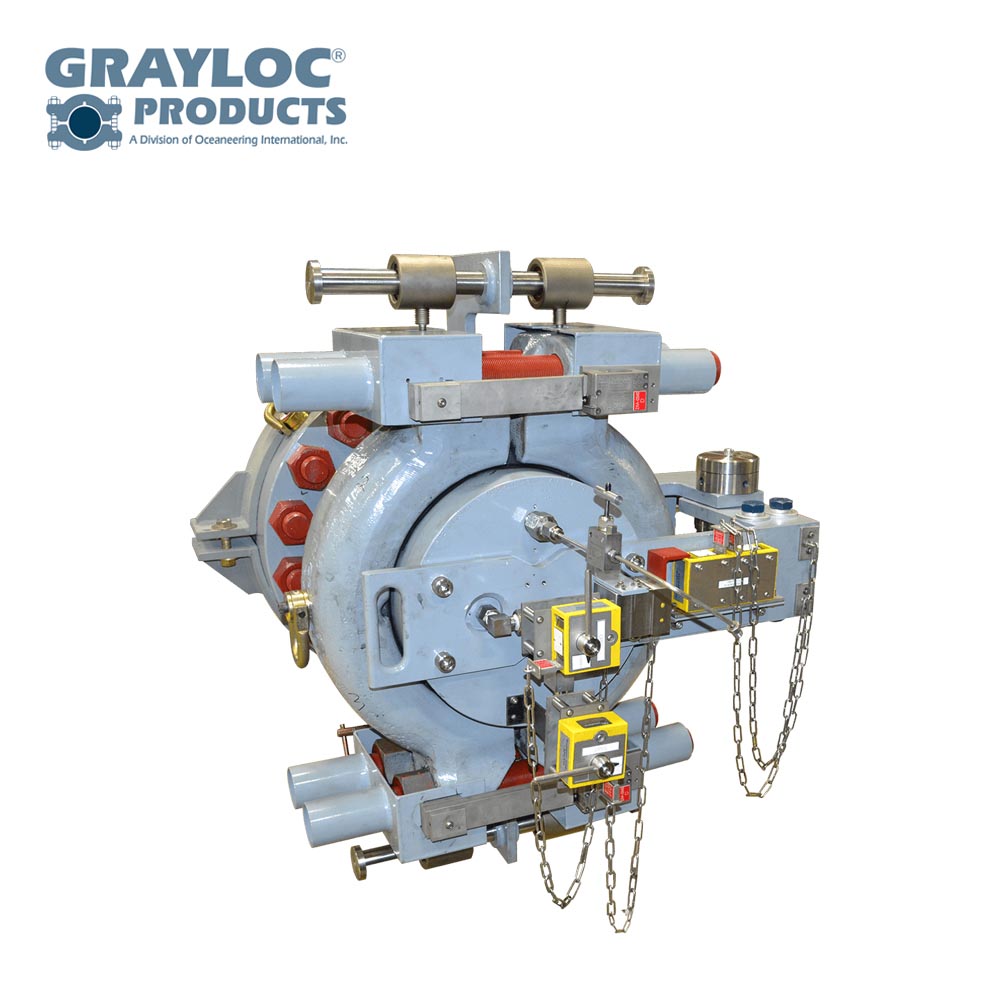

GRAYLOC® CLOSURE SYSTEMS

DESCRIPTION

Grayloc® closure systems incorporate the field-proven design features used in Grayloc connectors, and can be supplied with safety interlocks and hinge and clamp hanger support systems.

DESIGN TECHNOLOGY

>> Grayloc® metal-to-metal seal

>> Clamp hanger assemblies

>> Vertical- or horizontal-mounted, field-adjustable hinged door

>> Full ASME compliance with Section VIII Division 1, 2, and 3 code stamp capability

>> Safety interlock system options

>> Seal ring retention system

>> Available in horizontal and vertical arrangements

>> Compatible with hydraulic, pneumatic, and electric actuators

BENEFITS

>> Eliminates fugitive emissions with zero leakage seal (10-6 atm cc/s helium)

>> Reduces risk and increases operation safety

>> Opens/closes quickly with only a single operator and no mechanical lifting

>> Engineered for design pressures ranging from full vacuum to 48,000 psi

>> Lowers maintenance cost

>> Minimizes spare parts inventory

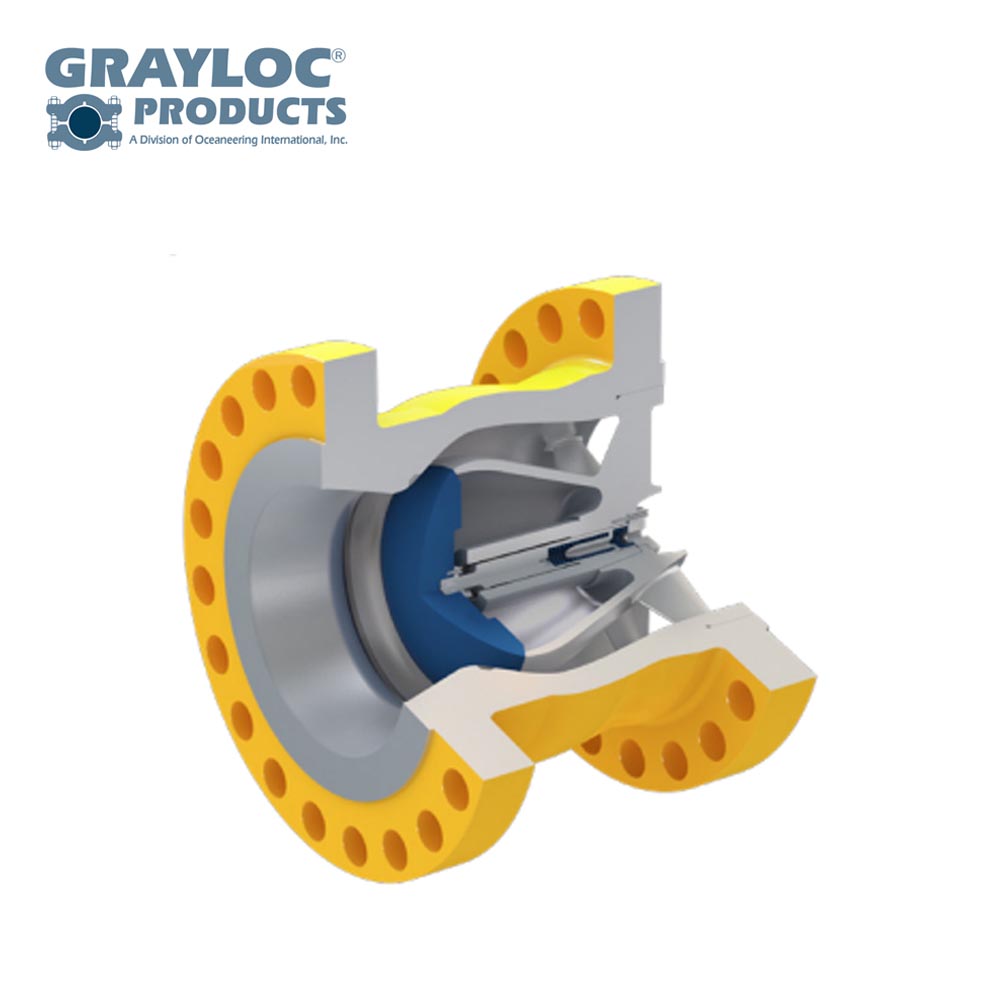

GRAYLOC® NON-SLAM NOZZLE CHECK VALVES

DESCRIPTION

Our field-proven non-slam nozzle check valves feature an innovative, maintenance-free, low-pressure-loss design that incorporates a unique, dual-spring closing action to provide a fast, dynamic response.

DESIGN TECHNOLOGY

>> Tight shut-off, metal-to-metal seal

>> Unique dual-spring design for fast, dynamic response

>> All-metal assembly (no elastomers)

>> ASME Class 150 through to 4,500 and up to API 10,000

>> Industry-standard end connections available, including Grayloc hubs and compact flanges

>> Sizes from 2 in to 60 in with a wide variety of body and trim materials

BENEFITS

>> Prevents return flow and water hammer with fast dynamic response

>> Optimized for low pressure loss

>> Maintenance-free design

>> Suitable for installation in any orientation (horizontal, vertical up or down, and diagonal)

>> Sized to eliminate disc chatter in low-flow conditions

>> Available from inventory, and expedited delivery can be accommodated

DOWNLOAD DOCUMENT

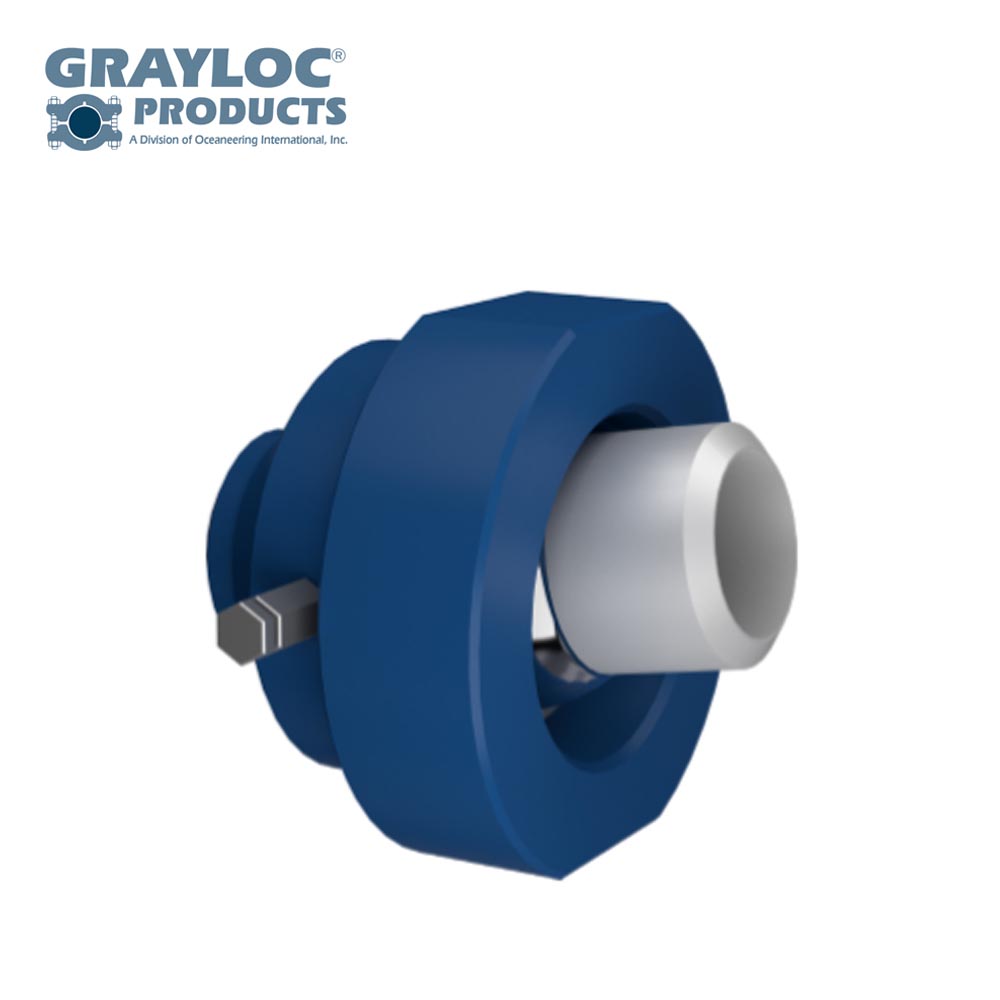

GRAYLOC® UNIVERSAL BALL JOINTS

DESCRIPTION

Our universal ball joints compensate for movement of piping and equipment while maintaining sealing integrity and relieving piping stresses. We provide reliable, serviceable, dynamic pipe connections suitable for use in steam, industrial, petrochemical, and marine applications.

DESIGN TECHNOLOGY

>> 360° continuous rotation and up to 30° axial pivot

>> Low-break torque limits stresses on adjoining pipe

>> Reliable high-temperature, high-pressure graphite seal

>> Field injection port supports simplified, tool-free, in-line maintenance

>> Compact, lightweight design delivered pre-assembled with butt weld ends or flanges

BENEFITS

>> Suitable for dynamic and static applications

>> Enables linear, rotational, or combined pipe movements

>> Compensates for thermal expansion, misalignment, and shifting equipment

>> Trusted in extreme and critical applications

>> Pre-torqued, hydrostatically tested and shipped ready for service

>> Fabricated, assembled, and tested expansion arm piping spools available

>> Available from inventory, and expedited delivery can be accommodated