Barton Firtop Engineering Company Limited was originally based in Clydebank, Scotland in the early 1900’s and were world renowned as winch manufacturers. In 1973 the Company was re-established at the present premises in Bromsgrove, Worcestershire, England and took over the designs and manufactures of its associate company G & A Firkins Ltd, manufacturers of the widely acclaimed ‘Firtop’ range of filters and strainers. In 1985 the management of the Company underwent a major restructuring programme and the decision was made to discontinue the winch deck machinery side of the business and to focus on the Filter and Strainer product lines, in which we now have over 50 years of experience.

INLINE BAG FILTER

Barton Firtop’s Inline Bag Filters offer a LARGER filtration area than similar strainers on the market, ensuring minimal pressure loss, improved flow-rates & greater dirt holding capacity, leading to longer service/ maintenance intervals.

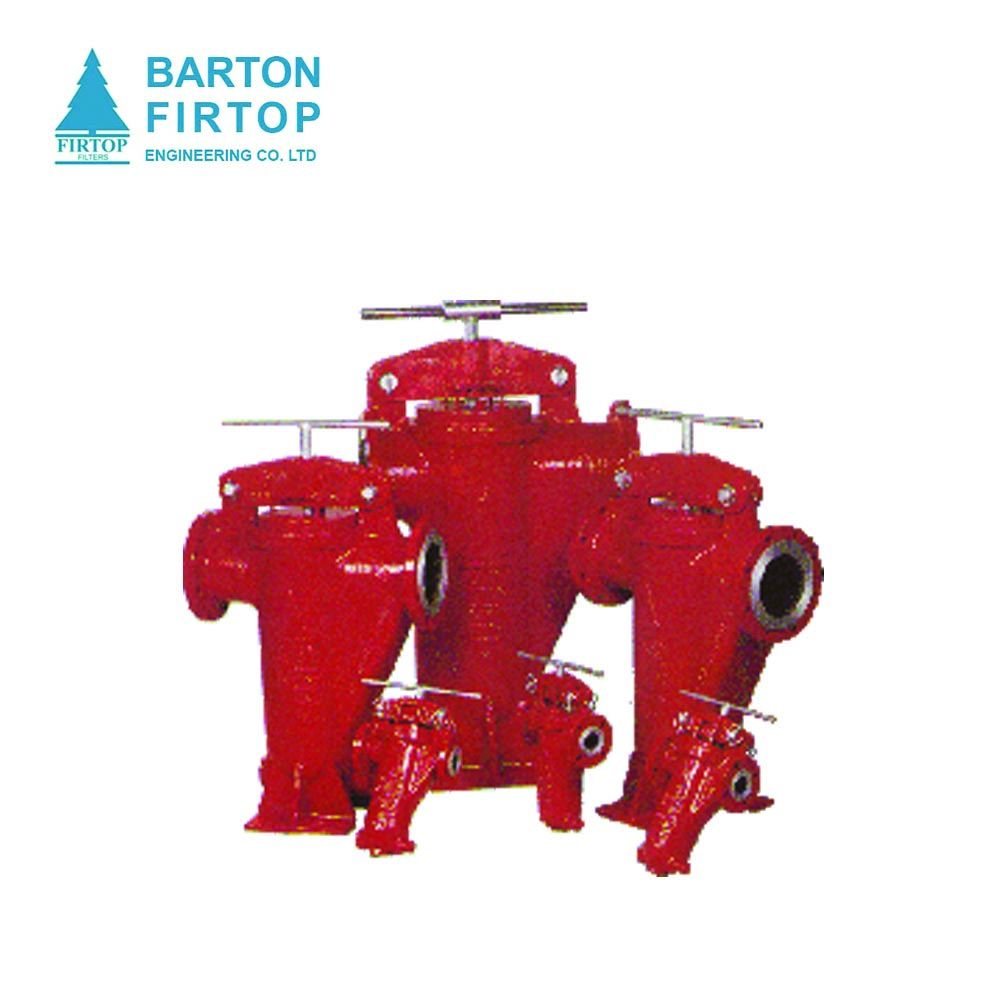

BASKET STRAINER

Barton Firtop’s Basket Strainers offer a LARGER filtration area than similar strainers on the market, ensuring minimal pressure loss, improved flow-rates & greater dirt holding capacity, leading to longer service/ maintenance intervals. The 150-300LB Basket Strainer, also known as Mono-in-line Strainer, is designed for the efficient removal of solid/foreign material from flowing liquids & gases. Our Quick Release range of Basket Strainers are manufactured to PED/97/23/EC with end connections machined to recognised International Standards such as ASME B16.5.

CONICAL STRAINERS

Conical strainers are designed for ‘temporary’ or short periods of operation, for example during commissioning and initial start-up periods of new or reconditioned process lines to remove any coarse debris such as rags, welding rods, pipe scale, rust etc accidentally or unavoidably present within the system.

BATH TUB STRAINERS

Fabricated “Bath Tub” Strainers, also known as fabricated “T-Type” Strainers, can be used as an alternative to our standard cast range in order to comply with specific project specifications. They are also generally more cost effective and readily available for larger sizes i.e. above 12″(300mm)NB and higher pressure.

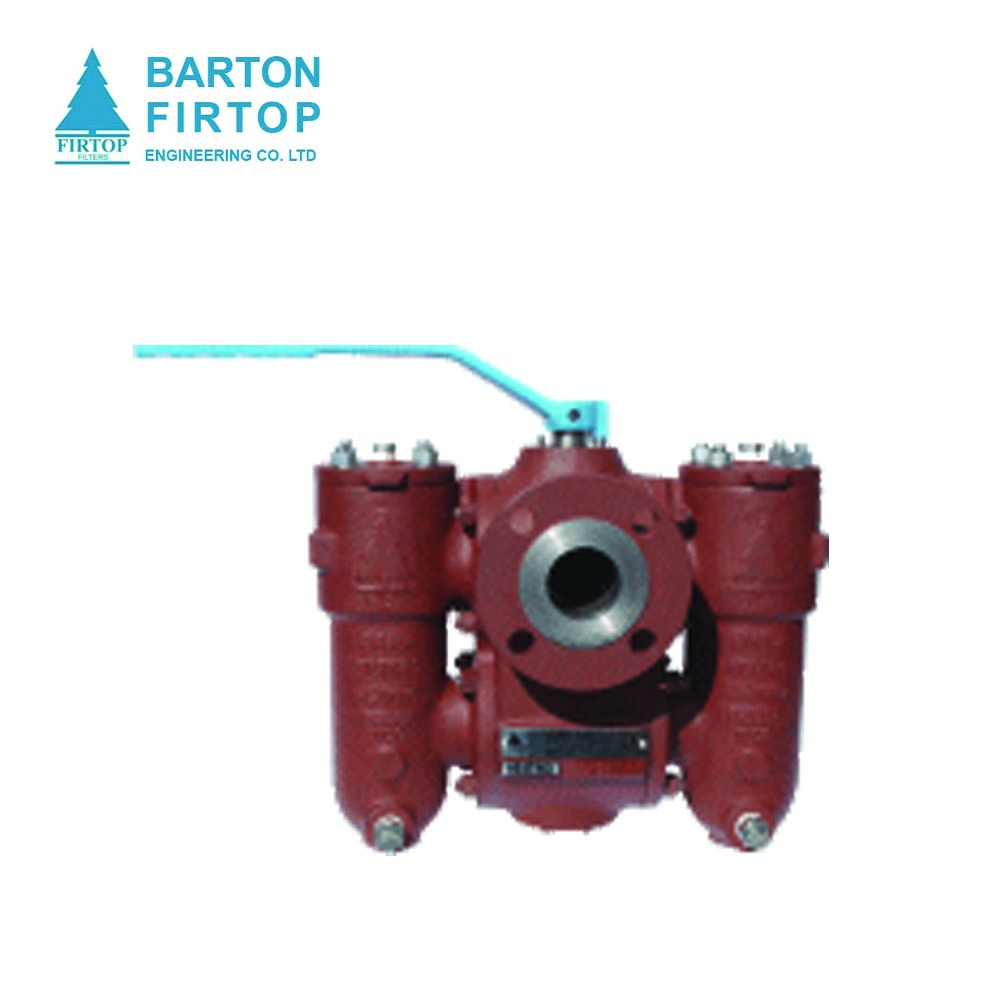

DUPLEX FIRPLEX STRAINERS

The ‘Firplex’ strainer is manufactured in a dual configuration with each strainer having two filter chambers. One chamber is on-line and the other on standby allowing continuous operation and no ‘down time’ during routine maintenance. Change-over between on-line and standby is achieved by utilising the integral ball valve system, which is controlled by a single lever.

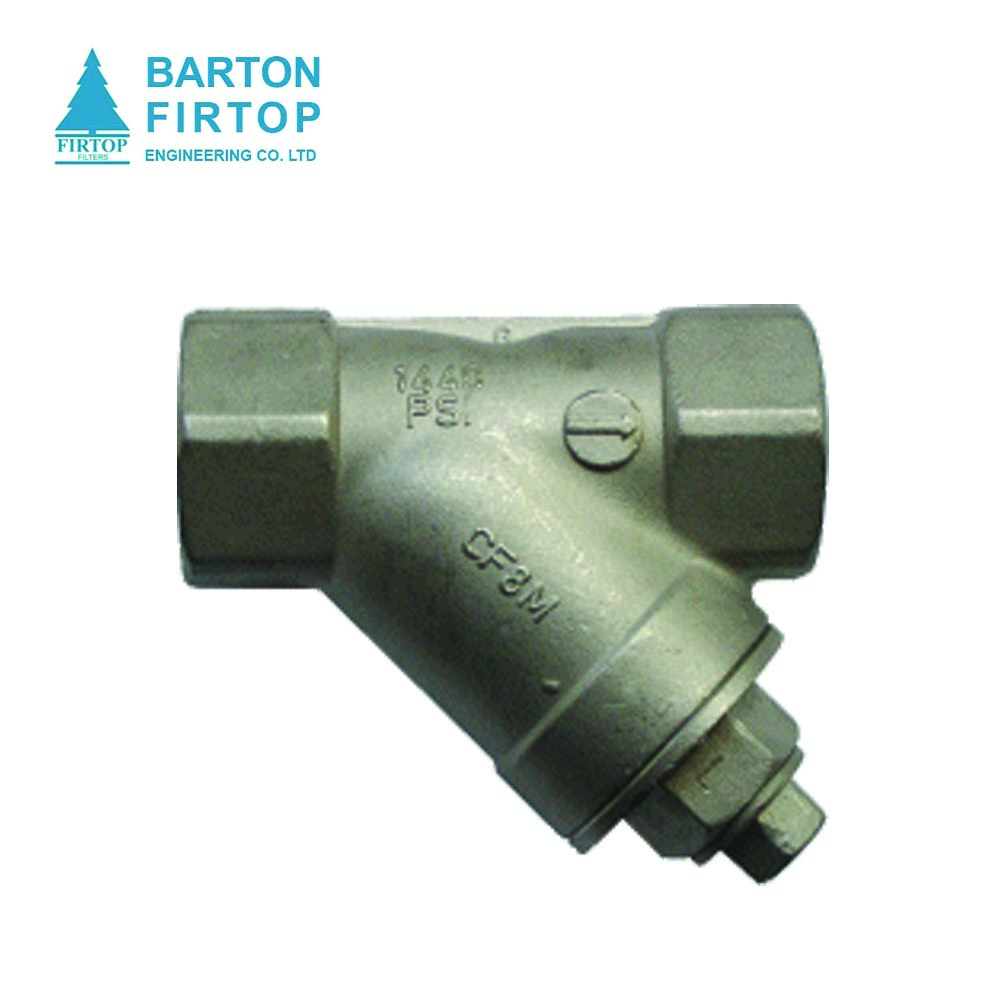

FLANGED Y-TYPE STRAINERS

The Y-Type Strainer is the most common & economic type of strainer for permanent applications, suitable for mounting in horizontal & vertical pipelines. Our Flanged Y-Type Strainers are designed and manufactured to PED/97/23/EC with end connections machined to recognised International standards such as ASME B16.5 and EN1092-1 (previously BS4504).